Page 408 - Air and Gas Drilling Manual

P. 408

9-12 Air and Gas Drilling Manual

tri-cone roller cutter insert type (nozzles 11/32 inches). The anticipated drilling rate

in a sandstone and limestone sequence in the interval is approximate 60 ft/hr. The

average rounded diameter of the rock cutting particles generated by this drill bit is

estimated to be 0.198 inch. The openhole interval below the casing shoe is to be

from 7,000 ft to 10,000 ft.

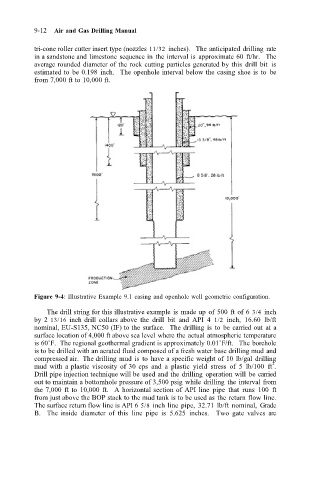

Figure 9-4: Illustrative Example 9.1 casing and openhole well geometric configuration.

The drill string for this illustrative example is made up of 500 ft of 6 3/4 inch

by 2 13/16 inch drill collars above the drill bit and API 4 1/2 inch, 16.60 lb/ft

nominal, EU-S135, NC50 (IF) to the surface. The drilling is to be carried out at a

surface location of 4,000 ft above sea level where the actual atmospheric temperature

is 60˚F. The regional geothermal gradient is approximately 0.01˚F/ft. The borehole

is to be drilled with an aerated fluid composed of a fresh water base drilling mud and

compressed air. The drilling mud is to have a specific weight of 10 lb/gal drilling

2

mud with a plastic viscosity of 30 cps and a plastic yield stress of 5 lb/100 ft .

Drill pipe injection technique will be used and the drilling operation will be carried

out to maintain a bottomhole pressure of 3,500 psig while drilling the interval from

the 7,000 ft to 10,000 ft. A horizontal section of API line pipe that runs 100 ft

from just above the BOP stack to the mud tank is to be used as the return flow line.

The surface return flow line is API 6 5/8 inch line pipe, 32.71 lb/ft nominal, Grade

B. The inside diameter of this line pipe is 5.625 inches. Two gate valves are