Page 439 - Air and Gas Drilling Manual

P. 439

1 826 6

,

.

.

.

0 426

19 47)

,

.

519 67

V

&

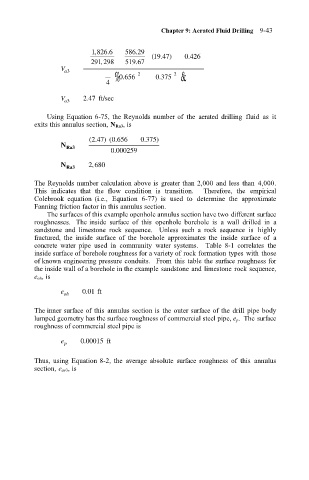

a3 291 298 % 586 29 (. Chapter 9: Aerated Fluid Drilling 9-43

2

2

.

.

4 0 656 0 375

V a3 247 ft/sec

.

Using Equation 6-75, the Reynolds number of the aerated drilling fluid as it

exits this annulus section, N Ra3, is

47

2

0

(. ) ( .656 . 0 375 )

N Ra3

. 0 000259

,

N Ra3 2 680

The Reynolds number calculation above is greater than 2,000 and less than 4,000.

This indicates that the flow condition is transition. Therefore, the empirical

Colebrook equation (i.e., Equation 6-77) is used to determine the approximate

Fanning friction factor in this annulus section.

The surfaces of this example openhole annulus section have two different surface

roughnesses. The inside surface of this openhole borehole is a wall drilled in a

sandstone and limestone rock sequence. Unless such a rock sequence is highly

fractured, the inside surface of the borehole approximates the inside surface of a

concrete water pipe used in community water systems. Table 8-1 correlates the

inside surface of borehole roughness for a variety of rock formation types with those

of known engineering pressure conduits. From this table the surface roughness for

the inside wall of a borehole in the example sandstone and limestone rock sequence,

e oh, is

e 001 ft

.

oh

The inner surface of this annulus section is the outer surface of the drill pipe body

lumped geometry has the surface roughness of commercial steel pipe, e p. The surface

roughness of commercial steel pipe is

.

e p 0 00015 ft

Thus, using Equation 8-2, the average absolute surface roughness of this annulus

section, e av3, is