Page 611 - Air and Gas Drilling Manual

P. 611

The diesel fuel consumption rate (in United States gallons) for the drilling depth of

10,000 ft is

222 8 . Chapter 11: Specialized Drilling Equipment 11-49

q 32 8 . gal/hr

f

(. )( .

0 8156 8 33)

Since there are two compressor units providing compressed air to this example

air hammer drilling operation, the total diesel fuel consumption rate while drilling at

the 10,000 ft of depth is approximately 66 gal/hr.

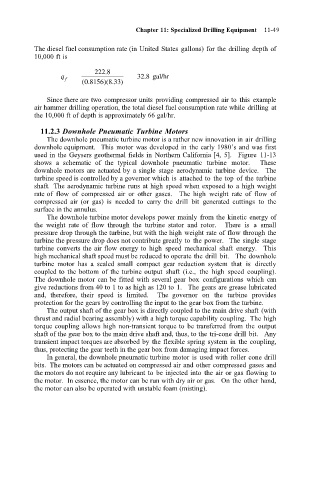

11.2.3 Downhole Pneumatic Turbine Motors

The downhole pneumatic turbine motor is a rather new innovation in air drilling

downhole equipment. This motor was developed in the early 1980’s and was first

used in the Geysers geothermal fields in Northern California [4, 5]. Figure 11-13

shows a schematic of the typical downhole pneumatic turbine motor. These

downhole motors are actuated by a single stage aerodynamic turbine device. The

turbine speed is controlled by a governor which is attached to the top of the turbine

shaft. The aerodynamic turbine runs at high speed when exposed to a high weight

rate of flow of compressed air or other gases. The high weight rate of flow of

compressed air (or gas) is needed to carry the drill bit generated cuttings to the

surface in the annulus.

The downhole turbine motor develops power mainly from the kinetic energy of

the weight rate of flow through the turbine stator and rotor. There is a small

pressure drop through the turbine, but with the high weight rate of flow through the

turbine the pressure drop does not contribute greatly to the power. The single stage

turbine converts the air flow energy to high speed mechanical shaft energy. This

high mechanical shaft speed must be reduced to operate the drill bit. The downhole

turbine motor has a sealed small compact gear reduction system that is directly

coupled to the bottom of the turbine output shaft (i.e., the high speed coupling).

The downhole motor can be fitted with several gear box configurations which can

give reductions from 40 to 1 to as high as 120 to 1. The gears are grease lubricated

and, therefore, their speed is limited. The governor on the turbine provides

protection for the gears by controlling the input to the gear box from the turbine.

The output shaft of the gear box is directly coupled to the main drive shaft (with

thrust and radial bearing assembly) with a high torque capability coupling. The high

torque coupling allows high non-transient torque to be transferred from the output

shaft of the gear box to the main drive shaft and, thus, to the tri-cone drill bit. Any

transient impact torques are absorbed by the flexible spring system in the coupling,

thus, protecting the gear teeth in the gear box from damaging impact forces.

In general, the downhole pneumatic turbine motor is used with roller cone drill

bits. The motors can be actuated on compressed air and other compressed gases and

the motors do not require any lubricant to be injected into the air or gas flowing to

the motor. In essence, the motor can be run with dry air or gas. On the other hand,

the motor can also be operated with unstable foam (misting).