Page 9 - An Introduction To Predictive Maintenance

P. 9

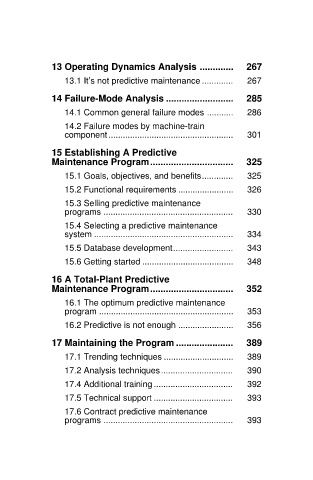

13 Operating Dynamics Analysis ............. 267

13.1 It’s not predictive maintenance ............. 267

14 Failure-Mode Analysis .......................... 285

14.1 Common general failure modes ........... 286

14.2 Failure modes by machine-train

component.................................................... 301

15 Establishing A Predictive

Maintenance Program................................ 325

15.1 Goals, objectives, and benefits............. 325

15.2 Functional requirements ....................... 326

15.3 Selling predictive maintenance

programs ...................................................... 330

15.4 Selecting a predictive maintenance

system .......................................................... 334

15.5 Database development......................... 343

15.6 Getting started ...................................... 348

16 A Total-Plant Predictive

Maintenance Program................................ 352

16.1 The optimum predictive maintenance

program ........................................................ 353

16.2 Predictive is not enough ....................... 356

17 Maintaining the Program ...................... 389

17.1 Trending techniques ............................. 389

17.2 Analysis techniques.............................. 390

17.4 Additional training ................................. 392

17.5 Technical support ................................. 393

17.6 Contract predictive maintenance

programs ...................................................... 393