Page 278 - Analytical method for food addtives

P. 278

3

4

UV at 230 nm

scanned from

20 to 81

m/z 77,

daltons

to 150 ºC for 1 min. Injector temp 220 ºC.

mA,

ions generated with argon set to 1.8 mtorr

temp 100 ºC. Isobutane for PICI. Product

temp prog 50 ºC for 1 min then 5 ºC/min

mm i.d., 0.25 µm)

MS/MS: 70 eV, 1300 V, 5 keV, 0.35

Inertsil 5C8 column. Acetonitrile–

water (90:10) mobile phase

energy set to –28 eV

silica capillary (0.32

PGEs derivatised with 3,5-dinitrobenzoyl

enzymatic assay of PG using commercial

(5 mL), centrifuged. Supernatant filtered

chloride. Reaction products dissolved in

PGEs extracted from foods and purified

filtered. Aliquot of filtrate subjected to

through 0.45 µm filter. Filtrate (2 mL)

enzymes (glycerol dehydrogenase and

by silica gel column chromatography.

Sample homogenised with water and

evaporated under N 2 to 0.2 mL

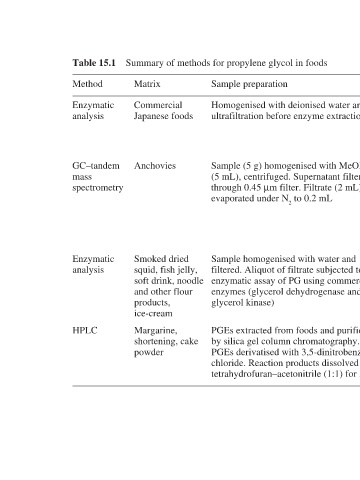

Summary of methods for propylene glycol in foods

Sample preparation Reference Detection Method conditions 1 Optical M NaCO 3 Filtrate (0.1 mL) + 1 mL 0.5 Homogenised with deionised water and density was mM NAD + buffer (pH 9.5) + 0.1 mL 200 ultrafiltration before enzyme extraction measured at (pH 9.5). Reaction started with 0.1 mL 340 nm of enzyme solution and incubated for m

glycerol kinase)

Matrix Commercial Japanese foods Anchovies Smoked dried squid, fish jelly, soft drink, noodle and other flour products, ice-cream Margarine, shortening, cake powder

Table 15.1 Method Enzymatic analysis GC–tandem mass spectrometry Enzymatic analysis HPLC