Page 75 - Analytical method for food addtives

P. 75

42 Analytical methods for food additives

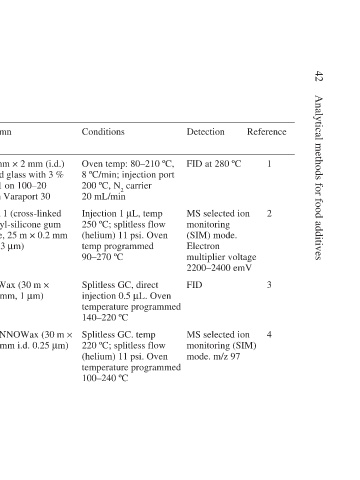

Reference 1 2 3 4

ºC multiplier voltage emV monitoring (SIM)

Detection FID at 280 MS selected ion monitoring (SIM) mode. Electron 2200–2400 FID MS selected ion mode. m/z 97

ºC, µL, temp psi. Oven µL. Oven psi. Oven

Conditions Oven temp: 80–210 ºC/min; injection port 8 ºC, N 2 carrier 200 mL/min 20 Injection 1 ºC; splitless flow 250 (helium) 11 temp programmed ºC 90–270 Splitless GC, direct injection 0.5 temperature programmed ºC 140–220 Splitless GC. temp ºC; splitless flow 220 (helium) 11 temperature programmed

mm (i.d.) % mm m × 0.2 m × µm) m × µm) mm i.d. 0.25

Column mm × 2 1.8 coiled glass with 3 OV-1 on 100–20 mesh Varaport 30 Ultra 1 (cross-linked methyl-silicone gum phase, 25 µm) × 0.33 DB-Wax (30 mm, 1 0.53 HP-INNOWax (30 0.25

Summary of methods for sorbic acid in foods Sample Matrix preparation/extraction Extracted with ether and into Foods aq NaOH and CH 2 Cl 2 . Converted to TMS esters Homogenised with water at Foods pH 1. Extracted into ether, evaporated, added acetonitrile. For GC evaporated acetonitrile and formed TMS esters Solvent extracti

Table 6.1 (a) Method GC GC–MS (SIM) GC GC-MS (SIM)