Page 27 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 27

66131_Ludwig_CH10A 5/30/2001 4:07 PM Page 17

Heat Transfer 17

8

Coil*

1

Studs 7

and nuts Manifold

lower*

2 3 4 5 6

Manifold Manifold Base plate Manifold Manifold

nuts lock rings gaskets upper*

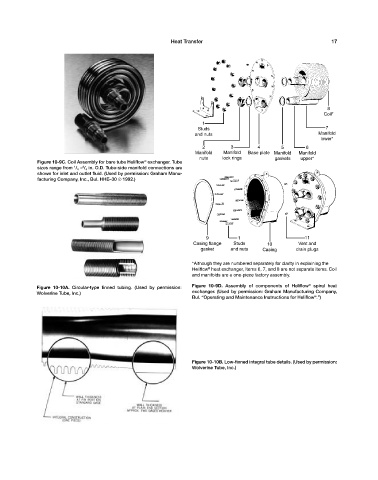

Figure 10-9C. Coil Assembly for bare tube Heliflow exchanger. Tube

®

sizes range from / 4 — / 4 in. O.D. Tube-side manifold connections are

1

3

shown for inlet and outlet fluid. (Used by permission: Graham Manu-

facturing Company, Inc., Bul. HHE–30 © 1992.)

9 1 11

Casing flange Studs 10 Vent and

gasket and nuts Casing drain plugs

*Although they are numbered separately for clarity in explaining the

®

Heliflow heat exchanger, Items 6, 7, and 8 are not separate items. Coil

and manifolds are a one-piece factory assembly.

Figure 10-10A. Circular-type finned tubing. (Used by permission: Figure 10-9D. Assembly of components of Heliflow ® spiral heat

Wolverine Tube, Inc.) exchanger. (Used by permission: Graham Manufacturing Company,

®

Bul. “Operating and Maintenance Instructions for Heliflow .”)

Figure 10-10B. Low-finned integral tube details. (Used by permission:

Wolverine Tube, Inc.)