Page 6 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 6

66131_Ludwig_FM 5/30/2001 4:04 PM Page vi

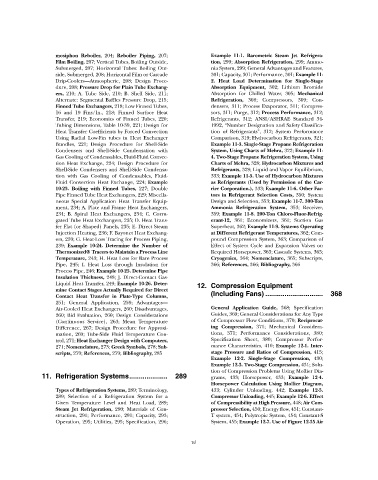

mosiphon Reboiler, 204; Reboiler Piping, 207; Example 11-1. Barometric Steam Jet Refrigera-

Film Boiling, 207; Vertical Tubes, Boiling Outside, tion, 299; Absorption Refrigeration, 299; Ammo-

Submerged, 207; Horizontal Tubes: Boiling Out- nia System, 299; General Advantages and Features,

side, Submerged, 208; Horizontal Film or Cascade 301; Capacity, 301; Performance, 301; Example 11-

Drip-Coolers—Atmospheric, 208; Design Proce- 2. Heat Load Determination for Single-Stage

dure, 208; Pressure Drop for Plain Tube Exchang- Absorption Equipment, 302; Lithium Bromide

ers, 210; A. Tube Side, 210; B. Shell Side, 211; Absorption for Chilled Water, 305; Mechanical

Alternate: Segmental Baffles Pressure Drop, 215; Refrigeration, 308; Compressors, 309; Con-

Finned Tube Exchangers, 218; Low Finned Tubes, densers, 311; Process Evaporator, 311; Compres-

16 and 19 Fins/In., 218; Finned Surface Heat sors, 311; Purge, 312; Process Performance, 312;

Transfer, 219; Economics of Finned Tubes, 220; Refrigerants, 312; ANSI/ASHRAE Standard 34-

Tubing Dimensions, Table 10-39, 221; Design for 1992, “Number Designation and Safety Classifica-

Heat Transfer Coefficients by Forced Convection tion of Refrigerants”, 312; System Performance

Using Radial Low-Fin tubes in Heat Exchanger Comparison, 319; Hydrocarbon Refrigerants, 321;

Bundles, 221; Design Procedure for Shell-Side Example 11-3. Single-Stage Propane Refrigeration

Condensers and Shell-Side Condensation with System, Using Charts of Mehra, 322; Example 11-

Gas Cooling of Condensables, Fluid-Fluid Convec- 4. Two-Stage Propane Refrigeration System, Using

tion Heat Exchange, 224; Design Procedure for Charts of Mehra, 328; Hydrocarbon Mixtures and

Shell-Side Condensers and Shell-Side Condensa- Refrigerants, 328; Liquid and Vapor Equilibrium,

tion with Gas Cooling of Condensables, Fluid- 333; Example 11-5. Use of Hydrocarbon Mixtures

Fluid Convection Heat Exchange, 224; Example as Refrigerants (Used by Permission of the Car-

10-23. Boiling with Finned Tubes, 227; Double rier Corporation.), 333; Example 11-6. Other Fac-

Pipe Finned Tube Heat Exchangers, 229; Miscella- tors in Refrigerant Selection Costs, 350; System

neous Special Application Heat Transfer Equip- Design and Selection, 353; Example 11-7. 300-Ton

ment, 234; A. Plate and Frame Heat Exchangers, Ammonia Refrigeration System, 353; Receiver,

234; B. Spiral Heat Exchangers, 234; C. Corru- 359; Example 11-8. 200-Ton Chloro-Fluor-Refrig-

gated Tube Heat Exchangers, 235; D. Heat Trans- erant-12, 361; Economizers, 361; Suction Gas

fer Flat (or Shaped) Panels, 235; E. Direct Steam Superheat, 362; Example 11-9. Systems Operating

Injection Heating, 236; F. Bayonet Heat Exchang- at Different Refrigerant Temperatures, 362; Com-

ers, 239; G. Heat-Loss Tracing for Process Piping, pound Compression System, 363; Comparison of

239; Example 10-24. Determine the Number of Effect of System Cycle and Expansion Valves on

Thermonized® Tracers to Maintain a Process Line Required Horsepower, 363; Cascade Systems, 363;

Temperature, 243; H. Heat Loss for Bare Process Cryogenics, 364; Nomenclature, 365; Subscripts,

Pipe, 245; I. Heat Loss through Insulation for 366; References, 366; Bibliography, 366

Process Pipe, 246; Example 10-25. Determine Pipe

Insulation Thickness, 248; J. Direct-Contact Gas-

Liquid Heat Transfer, 249; Example 10-26. Deter- 12. Compression Equipment

mine Contact Stages Actually Required for Direct

Contact Heat Transfer in Plate-Type Columns, (Including Fans) .............................. 368

251; General Application, 259; Advantages—

Air-Cooled Heat Exchangers, 260; Disadvantages, General Application Guide, 368; Specification

260; Bid Evaluation, 260; Design Considerations Guides, 369; General Considerations for Any Type

(Continuous Service), 263; Mean Temperature of Compressor Flow Conditions, 370; Reciprocat-

Difference, 267; Design Procedure for Approxi- ing Compression, 371; Mechanical Considera-

mation, 269; Tube-Side Fluid Temperature Con- tions, 371; Performance Considerations, 380;

trol, 271; Heat Exchanger Design with Computers, Specification Sheet, 380; Compressor Perfor-

271; Nomenclature, 273; Greek Symbols, 278; Sub- mance Characteristics, 410; Example 12-1. Inter-

scripts, 279; References, 279; Bibliography, 285 stage Pressure and Ratios of Compression, 415;

Example 12-2. Single-Stage Compression, 430;

Example 12-3. Two-Stage Compression, 431; Solu-

tion of Compression Problems Using Mollier Dia-

11. Refrigeration Systems.................... 289 grams, 433; Horsepower, 433; Example 12-4.

Horsepower Calculation Using Mollier Diagram,

Types of Refrigeration Systems, 289; Terminology, 433; Cylinder Unloading, 442; Example 12-5.

289; Selection of a Refrigeration System for a Compressor Unloading, 445; Example 12-6. Effect

Given Temperature Level and Heat Load, 289; of Compressibility at High Pressure, 448; Air Com-

Steam Jet Refrigeration, 290; Materials of Con- pressor Selection, 450; Energy flow, 451; Constant-

struction, 291; Performance, 291; Capacity, 293; T system, 454; Polytropic System, 454; Constant-S

Operation, 295; Utilities, 295; Specification, 296; System, 455; Example 12-7. Use of Figure 12-35 Air

vi