Page 125 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 125

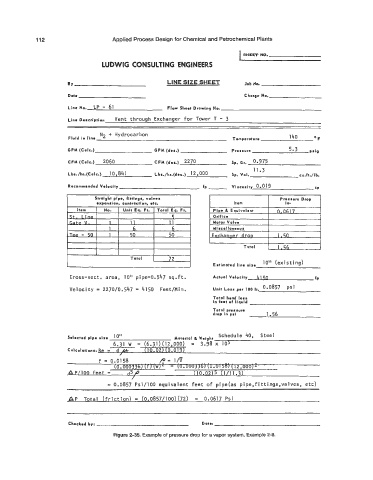

112 Applied Process Design for Chemical and Petrochemical Plants

snEEr NO.

LUDWIG CONSULTING ENGINEERS

BY LINE SIZE SHEET Job 210.

Date Charge No.

Line No. Lp - 61 Flow Sheet Drowi>ng No.

Vent through Exchanger for Tower T - 3

LineDescription

Np + Hydrocarbon

Fluid in line Temperature 140 OF

prig

GPM (Calc.) 2060 GPM (des.) 2270 Pressure 11.3 5.3 cu.ft./lb.

Sp. Gr. O.975

*

CFM (des.)

CFM (COIC.)

10,841

12,000

sp. Val.

Lbs./hr.(Colc.)

Lbs./hr.(des.)

Viscosity 0.019

Recommended Velocity

CP

fP ~

Total Eq. Ft.

No.

Unit Eq. Ft.

Item

5

St. 1 ine

I

I

1.56

Total

Total

Estimated line size Iott (existing)

Cross-sect. area, 10" pipe=O.547 sq.ft. Actual Velocity 41 r;n fp

Velocity = 2270/0.547 = 4150 Feet/Min. Unit ~ors per 100 ft. 0.0857 psi

Total head loss

in feet of liquid

Total pressure

drop in psi 1.56

Selected pipe size lo" Material L Weight Schedule 40, Steel

6.31 w = (6.31)(12,OOO) = 3.98 x 105

Colculatians:& $

=

1

f = 0.0158 e= 1/0 CL

(0.000336) (fJ (WJ' - - UUUjjb, (U.m [ IZ,000JL. .

.AP/IOO feet = (10.02)5 (1/11.3)

-

= 0.0857 Psi/lOO equivalent feet of pipe(as pipe,fittings,valves, etc)

,AP Total (friction) = (0.0857/100)(72) = 0.0617 Psi

~

Checked by: Date:

Figure 2-35. Example of pressure drop for a vapor system, Example 2-8.