Page 66 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 66

54 Applied Process Design for Chemical and Petrochemical Plants

gauge valve

Spira-tec trap _I t

leak indicator

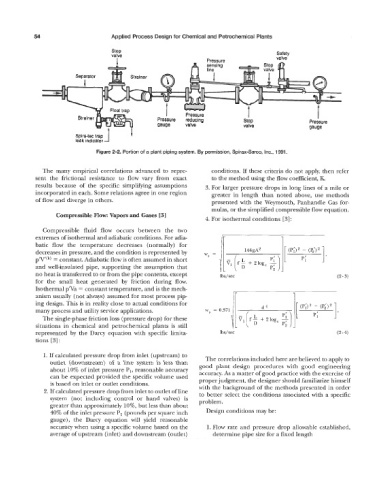

Figure 2-2. Portion of a plant piping system. By permission, Spirax-Sarco, Inc., 1991.

The many empirical correlations advanced to repre- conditions. If these criteria do not apply, then refer

sent the frictional resistance to flow vary from exact to the method using the flow coefficient, K

results because of the specific simplifylng assumptions 3. For larger pressure drops in long lines of a mile or

incorporated in each. Some relations agree in one region greater in length than noted above, use methods

of flow and diverge in others. presented with the Weymouth, Panhandle Gas for-

mulas, or the simplified compressible flow equation.

Compressible Flow: Vapors and Gases (31

4. For isothermal conditions [3]:

Compressible fluid flow occurs between the two

extremes of isothermal and adiabatic conditions. For adia-

batic flow the temperature decreases (normally) for

decreases in pressure, and the condition is represented by w, = -

p’V’ck) = constant. Adiabatic flow is often assumed in short L

and well-insulated pipe, supporting the assumption that D

no heat is transferred to or from the pipe contents, except lbs/sec (2 - 3)

for the small heat generated by friction during flow.

Isothermal p’Va = constant temperature, and is the mech-

anism usually (not always) assumed for most process pip- /I 1

ing design. This is in reality close to actual conditions for

many process and utility service applications.

The single-phase friction loss (pressure drop) for these

situations in chemical and petrochemical plants is still

represented by the Darcy equation with specific limita- lbs/sec (2 - 4)

tions [3]:

1. If calculated pressure drop from inlet (upstream) to The correlations included here are believed to apply to

outlet (downstream) of a line system is less than good plant design procedures with good engineering

about 10% of inlet pressure PI, reasonable accuracy

accuracy. As a matter of good practice with the exercise of

can be expected provided the specific volume used proper judgment, the designer should familiarize himself

is based on inlet or outlet conditions. with the background of the methods presented in order

2. If calculated pressure drop from inlet to outlet of line to better select the conditions associated with a specific

system (not including control or hand valves) is problem.

greater than approximately lo%, but less than about

40% of the inlet pressure PI (pounds per square inch Design conditions may be:

gauge), the Darcy equation will yield reasonable

accuracy when using a specific volume based on the 1. Flow rate and pressure drop allowable established,

average of upstream (inlet) and downstream (outlet) determine pipe size for a fixed length