Page 118 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 118

CH AP TER 5 .1 Transmissions and driveline

1st gear

2nd gear

1st gear – 31 teeth

2nd mainshaft

gear – 27 teeth

Mainshaft – 1000 rpm

Layshaft – 1st gear – 2214

rpm/2nd gear 1420 rpm

2nd layshaft

gear – 19 teeth 1st – 14 teeth

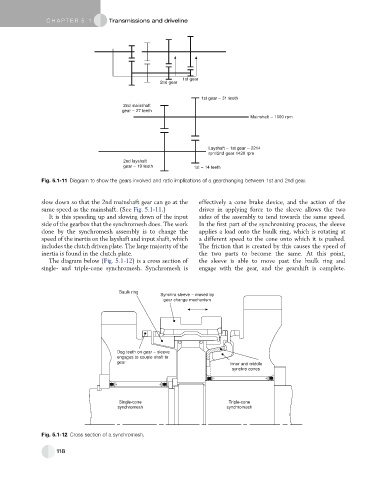

Fig. 5.1-11 Diagram to show the gears involved and ratio implications of a gearchanging between 1st and 2nd gear.

slow down so that the 2nd mainshaft gear can go at the effectively a cone brake device, and the action of the

same speed as the mainshaft. (See Fig. 5.1-11.) driver in applying force to the sleeve allows the two

It is this speeding up and slowing down of the input sides of the assembly to tend towards the same speed.

side of the gearbox that the synchromesh does. The work In the first part of the synchronizing process, the sleeve

done by the synchromesh assembly is to change the applies a load onto the baulk ring, which is rotating at

speed of the inertia on the layshaft and input shaft, which a different speed to the cone onto which it is pushed.

includes the clutch driven plate. The large majority of the The friction that is created by this causes the speed of

inertia is found in the clutch plate. the two parts to become the same. At this point,

The diagram below (Fig. 5.1-12) is a cross section of the sleeve is able to move past the baulk ring and

single- and triple-cone synchromesh. Synchromesh is engage with the gear, and the gearshift is complete.

Baulk ring

Synchro sleeve – moved by

gear change mechanism

Dog teeth on gear – sleeve

engages to couple shaft to

gear

Inner and middle

synchro cones

Single-cone Triple-cone

synchromesh synchromesh

Fig. 5.1-12 Cross section of a synchromesh.

118