Page 24 - Automotive Engineering

P. 24

Piston-engine cycles of operation CHAPTER 1.1

of the piston area and the mean effective cylinder pres-

sure is equal to the total piston thrust;

i:e: F ¼ pA

where F ¼ piston thrust (kN)

2

p ¼ mean effective pressure (kN/m )

2

and A ¼ cross-sectional area of piston (m )

The length of the piston stroke influences both the

turning-effort and the angular speed of the crankshaft.

This is because the crank-throw length determines the

leverage on the crankshaft, and the piston speed divided

by twice the stroke is equal to the crankshaft speed;

v

i:e: N ¼

2L

where N ¼ crankshaft speed (rev/min)

v ¼ piston speed (m/min)

and L ¼ piston stroke (m)

This means that making the stroke twice as long

doubles the crankshaft turning-effort and halves the Fig. 1.1-12 Illustration of compression-ratio.

crankshaft angular speed for a given linear piston speed.

The above shows that the engine performance is de-

cided by the ratio of bore to stroke chosen for a given that a very large number of repeated blows of consider-

cylinder capacity. able magnitude will strike the piston and so push it to-

wards ODC.

This description of compression, burning, and expan-

1.1.7 Compression-ratio sion of the gas charge shows the importance of utilising

a high degree of compression before burning takes place,

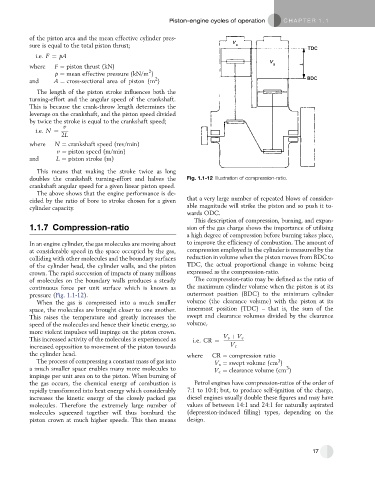

In an engine cylinder, the gas molecules are moving about to improve the efficiency of combustion. The amount of

at considerable speed in the space occupied by the gas, compression employed in the cylinder is measured by the

colliding with other molecules and the boundary surfaces reduction in volume when the piston moves from BDC to

of the cylinder head, the cylinder walls, and the piston TDC, the actual proportional change in volume being

crown. The rapid succession of impacts of many millions expressed as the compression-ratio.

of molecules on the boundary walls produces a steady The compression-ratio may be defined as the ratio of

continuous force per unit surface which is known as the maximum cylinder volume when the piston is at its

pressure (Fig. 1.1-12). outermost position (BDC) to the minimum cylinder

When the gas is compressed into a much smaller volume (the clearance volume) with the piston at its

space, the molecules are brought closer to one another. innermost position (TDC) – that is, the sum of the

This raises the temperature and greatly increases the swept and clearance volumes divided by the clearance

speed of the molecules and hence their kinetic energy, so volume,

more violent impulses will impinge on the piston crown.

This increased activity of the molecules is experienced as i:e: CR ¼ V s þ V c

increased opposition to movement of the piston towards V c

the cylinder head. where CR ¼ compression ratio

The process of compressing a constant mass of gas into V s ¼ swept volume (cm )

3

a much smaller space enables many more molecules to V c ¼ clearance volume (cm )

3

impinge per unit area on to the piston. When burning of

the gas occurs, the chemical energy of combustion is Petrol engines have compression-ratios of the order of

rapidly transformed into heat energy which considerably 7:1 to 10:1; but, to produce self-ignition of the charge,

increases the kinetic energy of the closely packed gas diesel engines usually double these figures and may have

molecules. Therefore the extremely large number of values of between 14:1 and 24:1 for naturally aspirated

molecules squeezed together will thus bombard the (depression-induced filling) types, depending on the

piston crown at much higher speeds. This then means design.

17