Page 496 - Battery Reference Book

P. 496

Types of charger 4813

Large battery installations such as one used by opera- When a battery on charge reaches a voltage of

tors of fleets of electric vehicles, for example in distri- between 2.35 and 2.40Vkell at the recommended

bution centres, require sophisticated battery charging charging rate, it is 75-80% charged. The time to

systems to obtain the best possible performance from termination of charge from this point is determined

the batteries and to protect the large investment of cash totally by the battery requirements and can vary over

involved. A good example of this type of charger for a wide range from say 1 to 6 h.

motive power batteries is the Spegel charger supplied

by Chloride Legg UK and this equipment is described The self-compensating charger therefore monitors

in some detail below. the battery voltage during the charging process and

Most chargers are designed so that, as the charging only when the stable voltage conditions achieved at the

process progresses and the battery voltage rises during top of charge are reached will the controller terminate

charge, the output current of the charger reduces. This charge. A typical layout of such a charger is shown in

charging characteristic is known as a ‘taper’ and is Figure 48.1.

described by referring to the current obtained near the This seemingly complicated device is used instead

beginning and near the end of a typical charge. of a voltage relay operating a switch at the end of

The position chosen near the beginning of the charge charge because the top-of-charge voltage of a battery

is 2.1 Vkell, and near the end of the charge 2.6 Vkell. varies according to its age, condition and temperature.

The values at these voltages are commonly expressed This would cause an old battery, which never reaches

as ratios. Hence, a charger designed to give an out- the tripping voltage, to go on receiving charge unnec-

put of lOOA at 2.1 V/cell and 50A at 2.6V/cell, is

said to have a taper characteristic of 2:l. The steep- essarily, or a new battery to reach the tripping voltage

ness of a charger taper is important because it affects too early and not receive the correct charge.

the charger’s sensitivity to variations in mains volt- For each individual charge cycle, the battery itself

age, the charging time required and the temperature determines exactly the amount of energy required, and

rise of the battery, which must be controlled during the fully self-compensating charger purely responds

charge. to this demand without manual adjustment. The use

A battery will accept a higher current at the start of sophisticated electronic control to monitor battery

of charge than at the end. However, the higher the condition permits recharge times for fully discharged

starting rate, the more expensive the charger is to make batteries of 7.5 h to be achieved using a straightforward

and buy. So, in practice, the steepness of the charger’s single-taper characteristic.

taper is usually a compromise between economics and

the battery’s requirements for the value of the finishing

current. In any event, the finishing current must be kept

below specified values: - a.c. input

1. It is necessary to restrict the temperature rise in the - - -&ircuit breaker

battery, as excessive temperature can damage its

plates and separators.

2. When the battery is between 75 and 80% charged,

oxygen and hydrogen gases are released owing to

chemical reaction within the cells. If the finishing

current is too high, the excessive flow of these gases

can dislodge particles of active material from the

positive plates, resulting in reduced battery life.

3. Nevertheless, gassing is an essential part of the

Transformer

charging process as it mixes the electrolyte. There- m

fore, the finishing rate must be sufficiently high to EBallast I - Spegel

allow this process, but not so high as to damage the 1 I I I controller

positive plates as described in (2). 1 4-

48.1 Types of charger

Ammeter

There are two basic types of charger. output to

batterv

Fuse I

48.1.1 Fully self-compensating chargers -

*

These are becoming increasingly popular as they o+

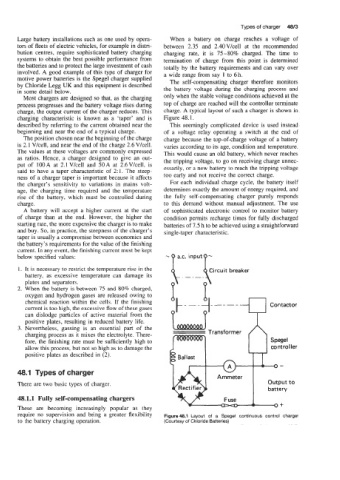

require no supervision and bring a greater flexibility Figure48.1 Layout of a Spegel continuous control charger

to the battery charging operation. (Courtesy of Chloride Batteries)