Page 276 - Biodegradable Polyesters

P. 276

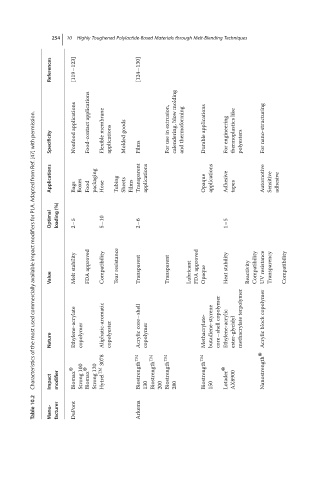

254 10 Highly Toughened Polylactide-Based Materials through Melt-Blending Techniques

References [119–123] [124–130]

applications applications membrane goods extrusion, molding blow thermoforming applications like nano-structuring

Characteristics of the most used commercially available impact modifiers for PLA. Adapted from Ref. [47] with permission.

Specificity Nonfood Food-contact Flexible applications Molded Films in use For calendering, and Durable engineering For thermoplastics polyesters For

Applications Bags Boxes Food packaging Hose Tubing Sheets Films Transparent applications Opaque applications Adhesive tapes Automotive Sensitive adhesive

Optimal loading (%) 2–5 5–10 2–6 1–5

stability approved Compatibility resistance Transparent Transparent approved stability Compatibility resistance Transparency Compatibility

Value Melt FDA Tear Lubricant FDA Opaque Heat Reactivity UV copolymer

Ethylene-acrylate Aliphatic-aromatic core–shell Methacrylate- butadiene-styrene copolymer Ethylene-acrylic ester-glycidyl methacrylate terpolymer block

Nature copolymer copolyester Acrylic copolymer core–shell Acrylic

3078 Nanostrength ®

120

100

Impact modifier Biomax ® Strong Biomax ® Strong Hytrel TM Biostrength TM 130 Biostrength TM 200 Biostrength TM 280 Biostrength TM 150 Lotader ® AX8900

Table 10.2 Manu- facturer DuPont Arkema