Page 50 - Biofuels Refining and Performance

P. 50

Energy and Its Biological Resources 33

Gas delivery

Inlet

3 2

1 Outlet and

GL vapors

c

(Above)

Ground level

4 4 (Below)

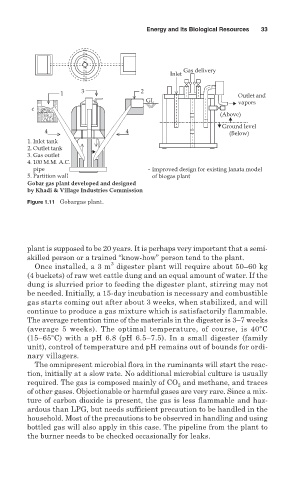

1. Inlet tank

2. Outlet tank

3. Gas outlet

4. 100 M.M. A.C.

pipe - Improved design for existing Janata model

5. Partition wall of biogas plant

Gobar gas plant developed and designed

by Khadi & Village Industries Commission

Figure 1.11 Gobargas plant.

plant is supposed to be 20 years. It is perhaps very important that a semi-

skilled person or a trained “know-how” person tend to the plant.

3

Once installed, a 3 m digester plant will require about 50–60 kg

(4 buckets) of raw wet cattle dung and an equal amount of water. If the

dung is slurried prior to feeding the digester plant, stirring may not

be needed. Initially, a 15-day incubation is necessary and combustible

gas starts coming out after about 3 weeks, when stabilized, and will

continue to produce a gas mixture which is satisfactorily flammable.

The average retention time of the materials in the digester is 3–7 weeks

(average 5 weeks). The optimal temperature, of course, is 40 C

(15–65 C) with a pH 6.8 (pH 6.5–7.5). In a small digester (family

unit), control of temperature and pH remains out of bounds for ordi-

nary villagers.

The omnipresent microbial flora in the ruminants will start the reac-

tion, initially at a slow rate. No additional microbial culture is usually

and methane, and traces

required. The gas is composed mainly of CO 2

of other gases. Objectionable or harmful gases are very rare. Since a mix-

ture of carbon dioxide is present, the gas is less flammable and haz-

ardous than LPG, but needs sufficient precaution to be handled in the

household. Most of the precautions to be observed in handling and using

bottled gas will also apply in this case. The pipeline from the plant to

the burner needs to be checked occasionally for leaks.