Page 81 - Biofuels Refining and Performance

P. 81

64 Chapter Two

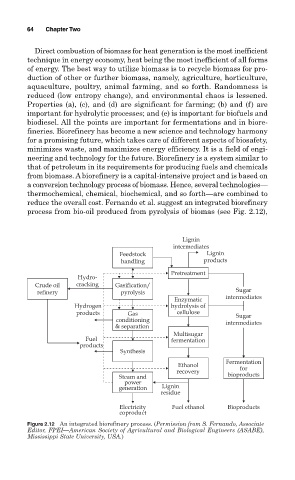

Direct combustion of biomass for heat generation is the most inefficient

technique in energy economy, heat being the most inefficient of all forms

of energy. The best way to utilize biomass is to recycle biomass for pro-

duction of other or further biomass, namely, agriculture, horticulture,

aquaculture, poultry, animal farming, and so forth. Randomness is

reduced (low entropy change), and environmental chaos is lessened.

Properties (a), (c), and (d) are significant for farming; (b) and (f) are

important for hydrolytic processes; and (e) is important for biofuels and

biodiesel. All the points are important for fermentations and in biore-

fineries. Biorefinery has become a new science and technology harmony

for a promising future, which takes care of different aspects of biosafety,

minimizes waste, and maximizes energy efficiency. It is a field of engi-

neering and technology for the future. Biorefinery is a system similar to

that of petroleum in its requirements for producing fuels and chemicals

from biomass. A biorefinery is a capital-intensive project and is based on

a conversion technology process of biomass. Hence, several technologies—

thermochemical, chemical, biochemical, and so forth—are combined to

reduce the overall cost. Fernando et al. suggest an integrated biorefinery

process from bio-oil produced from pyrolysis of biomas (see Fig. 2.12),

Lignin

intermediates

Feedstock Lignin

handling products

Pretreatment

Hydro-

Crude oil cracking Gasification/

refinery pyrolysis Sugar

Enzymatic intermediates

Hydrogen hydrolysis of

products Gas cellulose Sugar

conditioning intermediates

& separation

Multisugar

Fuel fermentation

products

Synthesis

Fermentation

Ethanol

recovery for

Steam and bioproducts

power

generation Lignin

residue

Electricity Fuel ethanol Bioproducts

coproduct

Figure 2.12 An integrated biorefinery process. (Permission from S. Fernando, Associate

Editor, FPEI—American Society of Agricultural and Biological Engineers (ASABE),

Mississippi State University, USA.)