Page 145 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 145

122 Biomass Gasification, Pyrolysis and Torrefaction

between torrefied pellet and raw wood pellet, we take this value to be

3

650 kg/m . So, the volumetric density of energy of torrefied pellet, EV p,t ,

would be

3

EV p;t 5 HHV t 3 ρ 5 24:59 3 650 MJ=m 5 15:98 GJ=m 3

p

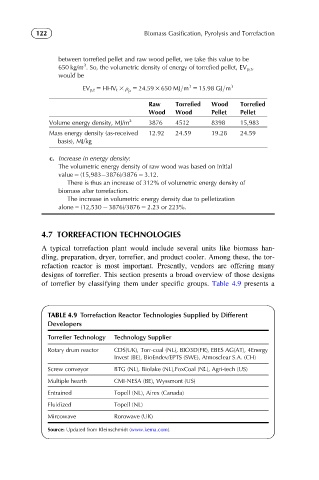

Raw Torrefied Wood Torrefied

Wood Wood Pellet Pellet

Volume energy density, MJ/m 3 3876 4512 8398 15,983

Mass energy density (as-received 12.92 24.59 19.28 24.59

basis), MJ/kg

c. Increase in energy density:

The volumetric energy density of raw wood was based on initial

value 5 (15,983 3876)/3876 5 3.12.

There is thus an increase of 312% of volumetric energy density of

biomass after torrefaction.

The increase in volumetric energy density due to pelletization

alone 5 (12,530 3876)/3876 5 2.23 or 223%.

4.7 TORREFACTION TECHNOLOGIES

A typical torrefaction plant would include several units like biomass han-

dling, preparation, dryer, torrefier, and product cooler. Among these, the tor-

refaction reactor is most important. Presently, vendors are offering many

designs of torrefier. This section presents a broad overview of those designs

of torrefier by classifying them under specific groups. Table 4.9 presents a

TABLE 4.9 Torrefaction Reactor Technologies Supplied by Different

Developers

Torrefier Technology Technology Supplier

Rotary drum reactor CDS(UK), Torr-coal (NL), BIO3D(FR), EBES AG(AT), 4Energy

Invest (BE), BioEndev/EPTS (SWE), Atmosclear S.A. (CH)

Screw conveyor BTG (NL), Biolake (NL),FoxCoal (NL), Agri-tech (US)

Multiple hearth CMI-NESA (BE), Wyssmont (US)

Entrained Topell (NL), Airex (Canada)

Fluidized Topell (NL)

Mircowave Rorowave (UK)

Source: Updated from Kleinschmidt (www.kema.com).