Page 186 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 186

Chapter | 5 Pyrolysis 163

Reaction II

Decarboxylation

Dehydration

carbonization

Reaction I

Active

Cellulose

cellulose

Reaction IV

Reaction III

Depolymerization Scission Secondary cracking

condensable gases Char, tar, non

condensable gases

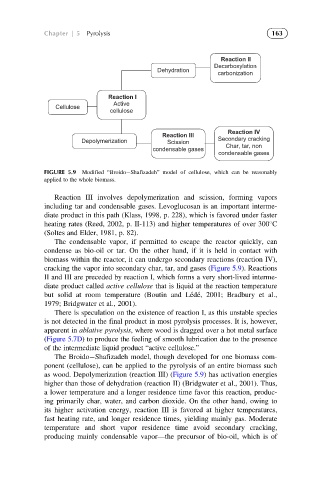

FIGURE 5.9 Modified “Broido Shafizadeh” model of cellulose, which can be reasonably

applied to the whole biomass.

Reaction III involves depolymerization and scission, forming vapors

including tar and condensable gases. Levoglucosan is an important interme-

diate product in this path (Klass, 1998, p. 228), which is favored under faster

heating rates (Reed, 2002, p. II-113) and higher temperatures of over 300 C

(Soltes and Elder, 1981, p. 82).

The condensable vapor, if permitted to escape the reactor quickly, can

condense as bio-oil or tar. On the other hand, if it is held in contact with

biomass within the reactor, it can undergo secondary reactions (reaction IV),

cracking the vapor into secondary char, tar, and gases (Figure 5.9). Reactions

II and III are preceded by reaction I, which forms a very short-lived interme-

diate product called active cellulose that is liquid at the reaction temperature

but solid at room temperature (Boutin and Le ´de ´, 2001; Bradbury et al.,

1979; Bridgwater et al., 2001).

There is speculation on the existence of reaction I, as this unstable species

is not detected in the final product in most pyrolysis processes. It is, however,

apparent in ablative pyrolysis, where wood is dragged over a hot metal surface

(Figure 5.7D) to produce the feeling of smooth lubrication due to the presence

of the intermediate liquid product “active cellulose.”

The Broido Shafizadeh model, though developed for one biomass com-

ponent (cellulose), can be applied to the pyrolysis of an entire biomass such

as wood. Depolymerization (reaction III) (Figure 5.9) has activation energies

higher than those of dehydration (reaction II) (Bridgwater et al., 2001). Thus,

a lower temperature and a longer residence time favor this reaction, produc-

ing primarily char, water, and carbon dioxide. On the other hand, owing to

its higher activation energy, reaction III is favored at higher temperatures,

fast heating rate, and longer residence times, yielding mainly gas. Moderate

temperature and short vapor residence time avoid secondary cracking,

producing mainly condensable vapor—the precursor of bio-oil, which is of