Page 372 - Biomedical Engineering and Design Handbook Volume 1, Fundamentals

P. 372

BIOMEDICAL COMPOSITES 349

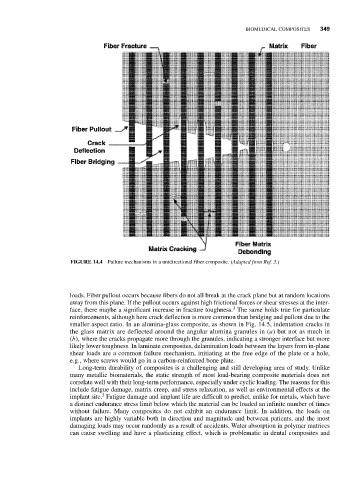

FIGURE 14.4 Failure mechanisms in a unidirectional fiber composite. (Adapted from Ref. 3.)

loads. Fiber pullout occurs because fibers do not all break at the crack plane but at random locations

away from this plane. If the pullout occurs against high frictional forces or shear stresses at the inter-

3

face, there maybe a significant increase in fracture toughness. The same holds true for particulate

reinforcements, although here crack deflection is more common than bridging and pullout due to the

smaller aspect ratio. In an alumina-glass composite, as shown in Fig. 14.5, indentation cracks in

the glass matrix are deflected around the angular alumina granules in (a) but not as much in

(b), where the cracks propagate more through the granules, indicating a stronger interface but more

likely lower toughness. In laminate composites, delamination loads between the layers from in-plane

shear loads are a common failure mechanism, initiating at the free edge of the plate or a hole,

e.g., where screws would go in a carbon-reinforced bone plate.

Long-term durability of composites is a challenging and still developing area of study. Unlike

many metallic biomaterials, the static strength of most load-bearing composite materials does not

correlate well with their long-term performance, especially under cyclic loading. The reasons for this

include fatigue damage, matrix creep, and stress relaxation, as well as environmental effects at the

2

implant site. Fatigue damage and implant life are difficult to predict, unlike for metals, which have

a distinct endurance stress limit below which the material can be loaded an infinite number of times

without failure. Many composites do not exhibit an endurance limit. In addition, the loads on

implants are highly variable both in direction and magnitude and between patients, and the most

damaging loads may occur randomly as a result of accidents. Water absorption in polymer matrices

can cause swelling and have a plasticizing effect, which is problematic in dental composites and