Page 306 - Biosystems Engineering

P. 306

Bioseparation Pr ocesses 283

A good bioseparation process should have the following properties:

1. Desired purity of the product

2. Stability of the product

3. Low cost

4. Reproducibility and scalability

5. Meet regulatory guidelines

Bioseparation processes have in common many familiar chemical

engineering unit operations (see Table 9.1). For example, aerobic fer-

mentations involve mixing three heterogeneous phases—microorgan-

ism, medium, and air. In the manufacture of antibiotics, mass transfer

(e.g., extraction, adsorption, and drying), heat transfer (such as evap-

oration, drying, and crystallization), and other mechanical operations

(e.g., cell rupture, settling thickening, filtration, and centrifuging) all

play a vital role. The investment on these operations is often claimed

to be about 4 times greater than that for the ferment or vessels and

their auxiliary equipment. Often, as much as 60 percent of the fixed

costs of fermentation are attributable to the recovery stage in organic

acid and amino acid production.

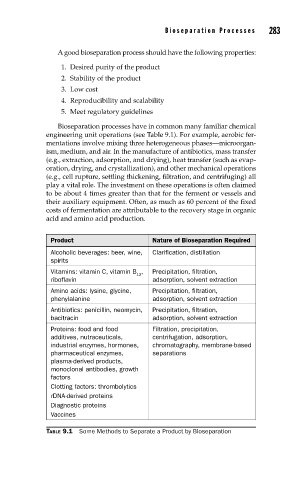

Product Nature of Bioseparation Required

Alcoholic beverages: beer, wine, Clarification, distillation

spirits

Vitamins: vitamin C, vitamin B , Precipitation, filtration,

12

riboflavin adsorption, solvent extraction

Amino acids: lysine, glycine, Precipitation, filtration,

phenylalanine adsorption, solvent extraction

Antibiotics: penicillin, neomycin, Precipitation, filtration,

bacitracin adsorption, solvent extraction

Proteins: food and food Filtration, precipitation,

additives, nutraceuticals, centrifugation, adsorption,

industrial enzymes, hormones, chromatography, membrane-based

pharmaceutical enzymes, separations

plasma-derived products,

monoclonal antibodies, growth

factors

Clotting factors: thrombolytics

rDNA-derived proteins

Diagnostic proteins

Vaccines

TABLE 9.1 Some Methods to Separate a Product by Bioseparation