Page 314 - Biosystems Engineering

P. 314

Bioseparation Pr ocesses 291

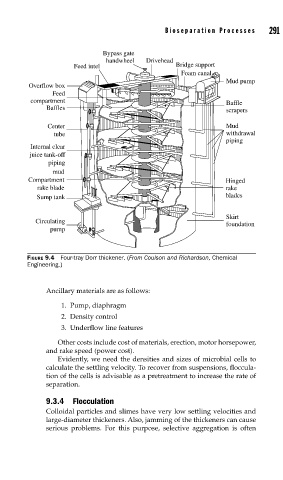

Bypass gate

handwheel Drivehead

Feed intel Bridge support

Foam canal

Mud pump

Overflow box

Feed

compartment Baffle

Baffles scrapers

Center Mud

tube withdrawal

piping

Internal clear

juice tank-off

piping

mud

Compartment Hinged

rake blade rake

Sump tank blades

Skirt

Circulating foundation

pump

FIGURE 9.4 Four-tray Dorr thickener. (From Coulson and Richardson, Chemical

Engineering.)

Ancillary materials are as follows:

1. Pump, diaphragm

2. Density control

3. Underflow line features

Other costs include cost of materials, erection, motor horsepower,

and rake speed (power cost).

Evidently, we need the densities and sizes of microbial cells to

calculate the settling velocity. To recover from suspensions, floccula-

tion of the cells is advisable as a pretreatment to increase the rate of

separation.

9.3.4 Flocculation

Colloidal particles and slimes have very low settling velocities and

large-diameter thickeners. Also, jamming of the thickeners can cause

serious problems. For this purpose, selective aggregation is often