Page 279 - Boiler_Operators_Handbook,_Second_Edition

P. 279

264 Boiler Operator’s Handbook

where the stress doesn’t go any higher. That’s where

the coupon is deforming so much that its cross sectional

area is reducing so, even though the stress in the coupon

increases, the force it can withstand decreases because

the area is decreasing. Shortly after the ultimate strength

is reached the material ruptures. If the coupon is not too

deformed we can measure the cross sectional area at the

rupture to determine the actual stress when it ruptured.

That’s how metal is tested and although you may never

see it done this explanation should give you a better un-

derstanding of material strength and what us engineers

are talking about.

Cast iron and similar materials, including concrete,

that are not extremely strong in tension but very strong

in compression are tested differently. The test method

helps describe what compressive stress is all about. A

Figure 9-1. Stress - strain diagram metal sample is machined to prescribed dimensions

over its entire length to form a test coupon. All those

pulls on the material the force or pull on the material is short round chunks of concrete you’ve seen laying

recorded. That value is converted to stress by dividing around any construction site are test coupons that were

by the cross sectional area of the specimen. poured. The coupon is placed in a machine with a firm

Modern machines allow the operator to enter the bottom plate and pressure is applied to the top of the

area on a keyboard so the machine also calculates the coupon. (Figure 9-2) The force applied by the machine

stress (pounds pull divided by the area in square inches) is divided by the cross-sectional area of the coupon

to imprint it on the diagram. The machine measures the to determine the stress. Some materials, like cast iron

change in distance between the two center punch marks and concrete, withstand considerable stress until they

to determine the strain. fail and they fail quickly when their yield strength is

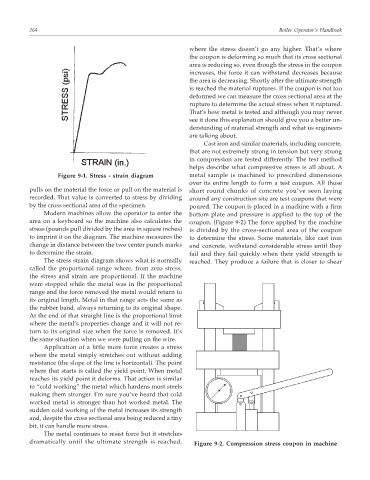

The stress strain diagram shows what is normally reached. They produce a failure that is closer to shear

called the proportional range where, from zero stress,

the stress and strain are proportional. If the machine

were stopped while the metal was in the proportional

range and the force removed the metal would return to

its original length. Metal in that range acts the same as

the rubber band, always returning to its original shape.

At the end of that straight line is the proportional limit

where the metal’s properties change and it will not re-

turn to its original size when the force is removed. It’s

the same situation when we were pulling on the wire.

Application of a little more force creates a stress

where the metal simply stretches out without adding

resistance (the slope of the line is horizontal). The point

where that starts is called the yield point. When metal

reaches its yield point it deforms. That action is similar

to “cold working” the metal which hardens most steels

making them stronger. I’m sure you’ve heard that cold

worked metal is stronger than hot worked metal. The

sudden cold working of the metal increases its strength

and, despite the cross sectional area being reduced a tiny

bit, it can handle more stress.

The metal continues to resist force but it stretches

dramatically until the ultimate strength is reached, Figure 9-2. Compression stress coupon in machine