Page 156 - Boiler plant and distribution system optimization manual

P. 156

Over 100 Ways to Improve Efficiency 141

most plants does not provide continuous or com- croprocessor is a powerful new tool that can take

plete information, there are a lot of blank spaces the pulse of your plant, detect problems and cal-

and assumptions about actual plant performance. culate efficiency every few seconds.

The computerized system (Figure 10.35) can

Advantages/Disadvantages store a tremendous amount of data and provide

Instruments add extra cost to plants and in clear and simple reports and graphics. With “In-

many cases they have not been installed or have telligent Programs” the computer can train your

been neglected. They must be kept calibrated and personnel and help them to diagnose problems

someone must record and analyze the data and very quickly. With a telephone connection, a plant

then take positive steps to correct energy wast- can be monitored by experts thousands of miles

ing conditions. This takes time, effort, money and away.

skill. However, there may be a large pay back The computer is truly the answer to tracking

in knowing what is happening and discovering plant performance. Let’s face it, a boiler is only a

where the fuel wasting conditions are. means of getting heat and power so the facility can

accomplish its mission. If steam could be brought

into a plant like electricity, many managers would

2. MONITOR AND MANAGE WITH be very happy because a great burden and liabili-

A MICROPROCESSOR BASED SYSTEM ty would be lifted from their shoulders. Until this

is possible, the next best thing to aid trouble free

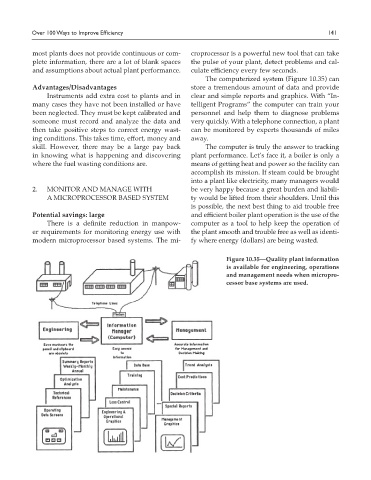

Potential savings: large and efficient boiler plant operation is the use of the

There is a definite reduction in manpow- computer as a tool to help keep the operation of

er requirements for monitoring energy use with the plant smooth and trouble free as well as identi-

modern microprocessor based systems. The mi- fy where energy (dollars) are being wasted.

Figure 10.35—Quality plant information

is available for engineering, operations

and management needs when micropro-

cessor base systems are used.