Page 178 - Build Your Own Combat Robot

P. 178

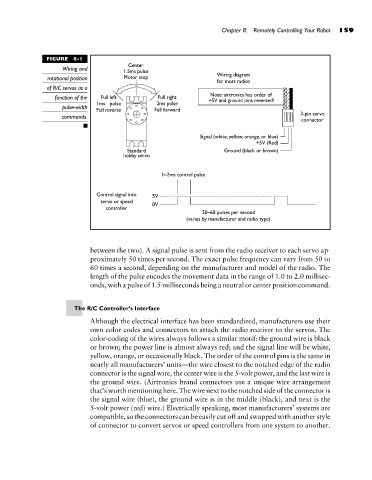

FIGURE 8-1 Chapter 8: Remotely Controlling Your Robot 159

Wiring and

rotational position

of R/C servos as a

function of the

pulse-width

commands.

between the two). A signal pulse is sent from the radio receiver to each servo ap-

proximately 50 times per second. The exact pulse frequency can vary from 50 to

60 times a second, depending on the manufacturer and model of the radio. The

length of the pulse encodes the movement data in the range of 1.0 to 2.0 millisec-

onds, with a pulse of 1.5 milliseconds being a neutral or center position command.

The R/C Controller’s Interface

Although the electrical interface has been standardized, manufacturers use their

own color codes and connectors to attach the radio receiver to the servos. The

color-coding of the wires always follows a similar motif: the ground wire is black

or brown; the power line is almost always red; and the signal line will be white,

yellow, orange, or occasionally black. The order of the control pins is the same in

nearly all manufacturers’ units—the wire closest to the notched edge of the radio

connector is the signal wire, the center wire is the 5-volt power, and the last wire is

the ground wire. (Airtronics brand connectors use a unique wire arrangement

that’s worth mentioning here. The wire next to the notched side of the connector is

the signal wire (blue), the ground wire is in the middle (black), and next is the

5-volt power (red) wire.) Electrically speaking, most manufacturers’ systems are

compatible, so the connectors can be easily cut off and swapped with another style

of connector to convert servos or speed controllers from one system to another.