Page 209 - Build Your Own Combat Robot

P. 209

Build Your Own Combat Robot

190

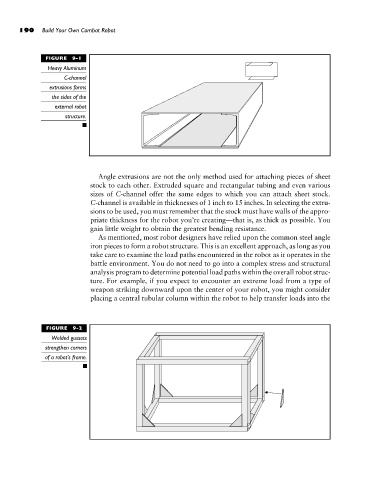

FIGURE 9-1

Heavy Aluminum

C-channel

extrusions forms

the sides of the

external robot

structure.

Angle extrusions are not the only method used for attaching pieces of sheet

stock to each other. Extruded square and rectangular tubing and even various

sizes of C-channel offer the same edges to which you can attach sheet stock.

C-channel is available in thicknesses of 1 inch to 15 inches. In selecting the extru-

sions to be used, you must remember that the stock must have walls of the appro-

priate thickness for the robot you’re creating—that is, as thick as possible. You

gain little weight to obtain the greatest bending resistance.

As mentioned, most robot designers have relied upon the common steel angle

iron pieces to form a robot structure. This is an excellent approach, as long as you

take care to examine the load paths encountered in the robot as it operates in the

battle environment. You do not need to go into a complex stress and structural

analysis program to determine potential load paths within the overall robot struc-

ture. For example, if you expect to encounter an extreme load from a type of

weapon striking downward upon the center of your robot, you might consider

placing a central tubular column within the robot to help transfer loads into the

FIGURE 9-2

Welded gussets

strengthen corners

of a robot’s frame.