Page 230 - Buried Pipe Design

P. 230

204 Chapter Four

occur in a given time. To establish the regression line, tests must be

conducted such that individual failures occur from 10 to 10,000 h

(1.14 years). The line is for static pressure only and temperature

controlled at 73.4 F.

For PVC pipe, long-term static pressure tests have been carried out

over more than 200,000 h (22.8 years) that confirm the validity of

establishing long-term hydrostatic strength on the basis of log-log

straight-line extrapolations.

Hydrostatic design stress. The hydrostatic design stress (HDS) is

defined in ASTM D 2241 as follows: “The estimated maximum ten-

sile stress in the wall of the pipe in the circumferential orientation

due to the internal hydrostatic water pressure that can be applied

continuously with a high degree of certainty that failure will not

occur.”

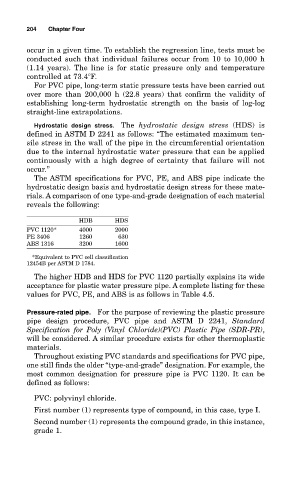

The ASTM specifications for PVC, PE, and ABS pipe indicate the

hydrostatic design basis and hydrostatic design stress for these mate-

rials. A comparison of one type-and-grade designation of each material

reveals the following:

HDB HDS

PVC 1120* 4000 2000

PE 3406 1260 630

ABS 1316 3200 1600

*Equivalent to PVC cell classification

12454B per ASTM D 1784.

The higher HDB and HDS for PVC 1120 partially explains its wide

acceptance for plastic water pressure pipe. A complete listing for these

values for PVC, PE, and ABS is as follows in Table 4.5.

Pressure-rated pipe. For the purpose of reviewing the plastic pressure

pipe design procedure, PVC pipe and ASTM D 2241, Standard

Specification for Poly (Vinyl Chloride)(PVC) Plastic Pipe (SDR-PR),

will be considered. A similar procedure exists for other thermoplastic

materials.

Throughout existing PVC standards and specifications for PVC pipe,

one still finds the older “type-and-grade” designation. For example, the

most common designation for pressure pipe is PVC 1120. It can be

defined as follows:

PVC: polyvinyl chloride.

First number (1) represents type of compound, in this case, type I.

Second number (1) represents the compound grade, in this instance,

grade 1.