Page 195 - CNC Robotics

P. 195

CNC Robotics

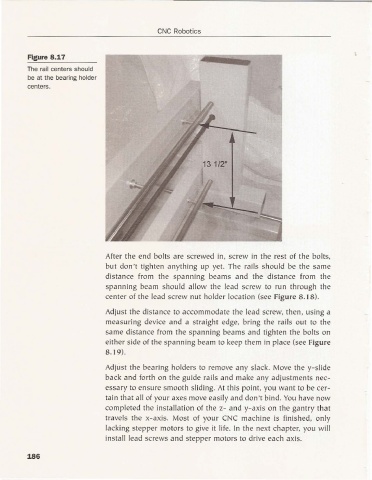

Agure 8.17

The rail centers should

be at the bearing holder

centers.

13 1/2"

After the end bolts are screwed in. screw in the rest of the bolts.

but don't tighten anything up yet. The rail s should be the same

distance from the spanning beams and the distance from the

spanning beam should allow the lead screw to ru n through the

center of the lead screw nut holder location (see Figure 8. 18).

Adj ust the distance to accommo date the lead screw. then. using a

measuring device and a straig ht edge. bring the rails out to the

same distance from the spanning beams and tighten the bo lts on

either side of the span ni ng beam to keep them in place (see Figure

8. 19).

Adjust the bearing ho lders to remove any slack. Move the y-slide

back and forth on th e guide rails and make any adjustm ents nec-

essary to ensure smooth sliding. At this point, yo u wa nt to be cer-

tain that all of your axes move easily and don't bind. You have now

completed the in stallation of the z- and y-axis on the gantry that

travels the x-axis, Mo st of your CNC machine is finished. only

lacking stepper motors to give it life. In the next chapter, you w ill

install lead screws an d stepper motors to drive each axis.

186