Page 266 - Carbon Nanotube Fibres and Yarns

P. 266

256 Carbon Nanotube Fibers and Yarns

Metal filament CNT yarn Metal filament –600

CNT

CNT yarn –500 Pt+CNT

Au+CNT

AuAg+CNT

–400 Ag+CNT

Z" (ohm) –300 Cu+CNT

PtCu+CNT

PVA-H 3 PO 4 coating

–200

Electrode 2 Electrode 1

–100

PVA-H 3 PO 4 coating

0

0 50 100 150 200 250 300 1000 2000 3000

Multi-ply yarn supercapacitor Z' (ohm)

(A) (B)

1.5

100

80 Cu+CNT 1.0

Current density (A/g) 40 1.0 V Potential (V) 0.5 Cu+CNT

60

1.2 V

1.0 V

1.4 V

20

1.2 V

1.4 V

–20 0

0.0

–40

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 0 5 10 15 20 25 30

(C) Potential (V) (D) Time (S)

70

80

60

50 Cu+CNT Cu+CNT

Capacitance (F/g) 40 Energy density (Wh/kg) 60

40

30

20

10 20

0 0

1.0 1.1 1.2 1.3 1.4 1.5 0 50000 100000 150000

(E) Potential (V) (F) Power density (W/kg)

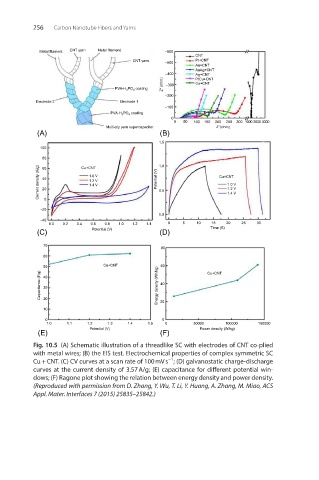

Fig. 10.5 (A) Schematic illustration of a threadlike SC with electrodes of CNT co-plied

with metal wires; (B) the EIS test. Electrochemical properties of complex symmetric SC

−1

Cu + CNT. (C) CV curves at a scan rate of 100 mV s ; (D) galvanostatic charge-discharge

curves at the current density of 3.57 A/g; (E) capacitance for different potential win-

dows; (F) Ragone plot showing the relation between energy density and power density.

(Reproduced with permission from D. Zhang, Y. Wu, T. Li, Y. Huang, A. Zhang, M. Miao, ACS

Appl. Mater. Interfaces 7 (2015) 25835–25842.)