Page 416 - Centrifugal Pumps 2E

P. 416

Mechanical Seals 381

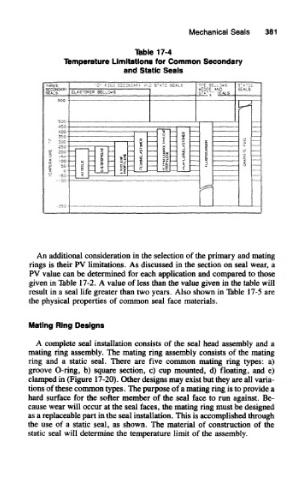

Table 17-4

Temperature Limitations for Common Secondary

and Static Seals

An additional consideration in the selection of the primary and mating

rings is their PV limitations. As discussed in the section on seal wear, a

PV value can be determined for each application and compared to those

given in Table 17-2. A value of less than the value given in the table will

result in a seal life greater than two years. Also shown in Table 17-5 are

the physical properties of common seal face materials.

Mating Ring Designs

A complete seal installation consists of the seal head assembly and a

mating ring assembly. The mating ring assembly consists of the mating

ring and a static seal. There are five common mating ring types; a)

groove O-ring, b) square section, c) cup mounted, d) floating, and e)

clamped in (Figure 17-20). Other designs may exist but they are all varia-

tions of these common types. The purpose of a mating ring is to provide a

hard surface for the softer member of the seal face to run against. Be-

cause wear will occur at the seal faces, the mating ring must be designed

as a replaceable part in the seal installation. This is accomplished through

the use of a static seal, as shown. The material of construction of the

static seal will determine the temperature limit of the assembly.