Page 204 - Centrifugal Pumps Design and Application

P. 204

178 Centrifugal Pumps: Design and Application

flow. Very high suction pressures move the cutoff point to higher flow

rates.

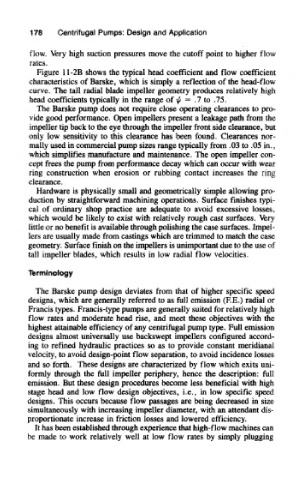

Figure 11-2B shows the typical head coefficient and flow coefficient

characteristics of Barske, which is simply a reflection of the head-flow

curve. The tall radial blade impeller geometry produces relatively high

head coefficients typically in the range of ^ = .7 to .75.

The Barske pump does not require close operating clearances to pro-

vide good performance. Open impellers present a leakage path from the

impeller tip back to the eye through the impeller front side clearance, but

only low sensitivity to this clearance has been found. Clearances nor-

mally used in commercial pump sizes range typically from .03 to .05 in.,

which simplifies manufacture and maintenance. The open impeller con-

cept frees the pump from performance decay which can occur with wear

ring construction when erosion or rubbing contact increases the ring

clearance.

Hardware is physically small and geometrically simple allowing pro-

duction by straightforward machining operations. Surface finishes typi-

cal of ordinary shop practice are adequate to avoid excessive losses,

which would be likely to exist with relatively rough cast surfaces. Very

little or no benefit is available through polishing the case surfaces. Impel-

lers are usually made from castings which are trimmed to match the case

geometry. Surface finish on the impellers is unimportant due to the use of

tall impeller blades, which results in low radial flow velocities.

Terminology

The Barske pump design deviates from that of higher specific speed

designs, which are generally referred to as fall emission (RE.) radial or

Francis types. Francis-type pumps are generally suited for relatively high

flow rates and moderate head rise, and meet these objectives with the

highest attainable efficiency of any centrifugal pump type. Full emission

designs almost universally use backswept impellers configured accord-

ing to refined hydraulic practices so as to provide constant meridianal

velocity, to avoid design-point flow separation, to avoid incidence losses

and so forth. These designs are characterized by flow which exits uni-

formly through the full impeller periphery, hence the description: full

emission. But these design procedures become less beneficial with high

stage head and low flow design objectives, i.e., in low specific speed

designs. This occurs because flow passages are being decreased in size

simultaneously with increasing impeller diameter, with an attendant dis-

proportionate increase in friction losses and lowered efficiency.

It has been established through experience that high-flow machines can

be made to work relatively well at low flow rates by simply plugging