Page 217 - Centrifugal Pumps Design and Application

P. 217

High Speed Pumps 191

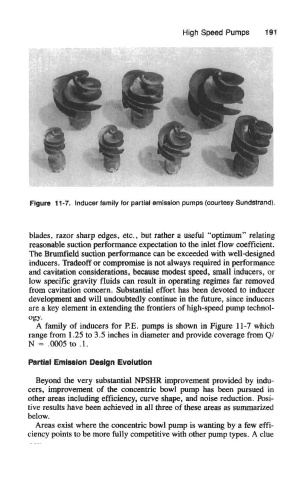

Figure 11-7. Inducer family for partial emission pumps (courtesy Sundstrand)

blades, razor sharp edges, etc., but rather a useful "optimum" relating

reasonable suction performance expectation to the inlet flow coefficient.

The Brumfield suction performance can be exceeded with well-designed

inducers. Tradeoff or compromise is not always required in performance

and cavitation considerations, because modest speed, small inducers, or

low specific gravity fluids can result in operating regimes far removed

from cavitation concern. Substantial effort has been devoted to inducer

development and will undoubtedly continue in the future, since inducers

are a key element in extending the frontiers of high-speed pump technol-

ogy-

A family of inducers for RE. pumps is shown in Figure 11-7 which

range from 1.25 to 3.5 inches in diameter and provide coverage from Q/

N = .0005 to .1.

Partial Emission Design Evolution

Beyond the very substantial NPSHR improvement provided by indu-

cers, improvement of the concentric bowl pump has been pursued in

other areas including efficiency, curve shape, and noise reduction. Posi-

tive results have been achieved in all three of these areas as summarized

below.

Areas exist where the concentric bowl pump is wanting by a few effi-

ciency points to be more fully competitive with other pump types. A clue