Page 235 - Centrifugal Pumps Design and Application

P. 235

Double-Case Pumps 209

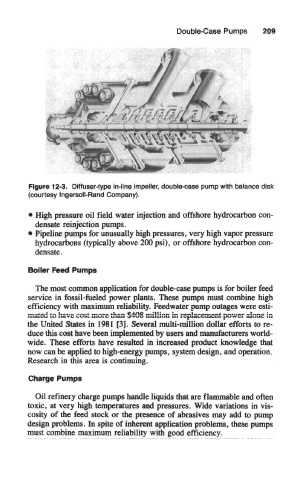

Figure 12-3. Diffuser-type in-line impeller, double-case pump with balance disk

(courtesy Ingersoll-Rand Company).

• High pressure oil field water injection and offshore hydrocarbon eon-

densate reinjection pumps.

* Pipeline pumps for unusually high pressures, very high vapor pressure

hydrocarbons (typically above 200 psi), or offshore hydrocarbon con-

densate.

Boiler Feed Pumps

The most common application for double-case pumps is for boiler feed

service in fossil-fueled power plants. These pumps must combine high

efficiency with maximum reliability. Feedwater pump outages were esti-

mated to have cost more than $408 million in replacement power alone in

the United States in 1981 [3]. Several multi-million dollar efforts to re-

duce this cost have been implemented by users and manufacturers world-

wide. These efforts have resulted in increased product knowledge that

now can be applied to high-energy pumps, system design, and operation.

Research in this area is continuing.

Charge Pumps

Oil refinery charge pumps handle liquids that are flammable and often

toxic, at very high temperatures and pressures. Wide variations in vis-

cosity of the feed stock or the presence of abrasives may add to pump

design problems. In spite of inherent application problems, these pumps

must combine maximum reliability with good efficiency.