Page 265 - Centrifugal Pumps Design and Application

P. 265

Slurry Pumps 237

There is little to be gained by fitting a rear wear plate, provided the

rear of the hard metal casing extends to the stuffing box. Experience has

shown that the rate of wear in this area is not any greater than in the cas-

ing itself.

Bearing Frames

Usually the bearings are oil lubricated with a calculated life of over

50,000 hours. Slurry pumps are installed in dirty dust-laden atmo-

spheres, and extra precautions have to be taken to seal the bearing covers

and prevent the ingress of liquid and dust. In severe services, taconite

seals are provided (i.e. double-lip type seals with grease cavities).

Sealing

Slurry pumps are often subjected to severe shock loading and shaft

whip due to the presence of solids and system upsets. For these reasons

soft compression packing is still favored as a means of sealing at the

stuffing box.

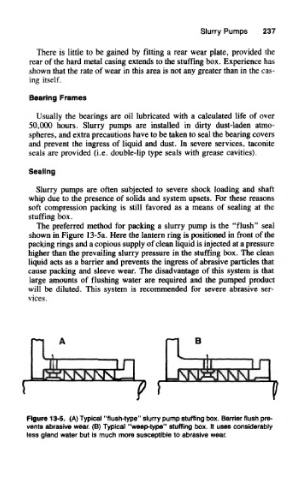

The preferred method for packing a slurry pump is the "flush" seal

shown in Figure 13-5a. Here the lantern ring is positioned in front of the

packing rings and a copious supply of clean liquid is injected at a pressure

higher than the prevailing slurry pressure in the stuffing box. The clean

liquid acts as a barrier and prevents the ingress of abrasive particles that

cause packing and sleeve wear. The disadvantage of this system is that

large amounts of flushing water are required and the pumped product

will be diluted. This system is recommended for severe abrasive ser-

vices.

Figure 13-5. (A) Typical "flush-type" slurry pump stuffing box. Barrier flush pre-

vents abrasive wear. (B) Typical "weep-type" stuffing box. It uses considerably

less gland water but is much more susceptible to abrasive wear.