Page 383 - Chemical Process Equipment - Selection and Design

P. 383

346 DISINTEGRATION, AGGLOMERATION, AND SIZE SEPARATION OF PARTICULATE SOLIDS

AHFlywheel

Feed

F/ywhee/

/Relief

spring

Discharge

(b)

C ~ 650 fprn ~400 fprn 250 fprn ~ ~ ~ ~ )

~

?&-in. ball 2L5-in. ball

crushing crushing

I-in. material %-in. material

=43:1 = 125:l

111 ion

& Periphval tlischnrge 4 discharge

when required

(e) (f 1

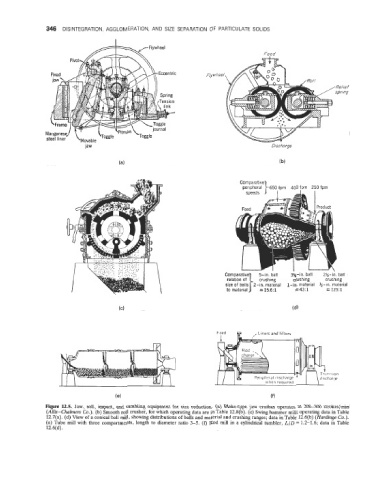

Figure 12.5. Jaw, roll, impact, and tumbling equipment for size reduction. (a) Blake-type jaw crusher operates at 200-300 strokes/min

(Allis-Chalmers Co.). (b) Smooth roll crusher, for which operating data are in Table 12.8(b). (c) Swing hammer mill; operating data in Table

12.7(a). (d) View of a conical ball mill, showing distributions of balls and material and crushing ranges; data in Table 12.6(b) (Hardinge Co.).

(e) Tube mill with three compartments, length to diameter ratio 3-5. (f) Rod mill in a cylindrical tumbler, LID = 1.2-1.6; data in Table

12.6(d).