Page 228 - Chemical and process design handbook

P. 228

Speight_Part II_C 11/7/01 3:08 PM Page 2.168

CHLOROPRENE

o

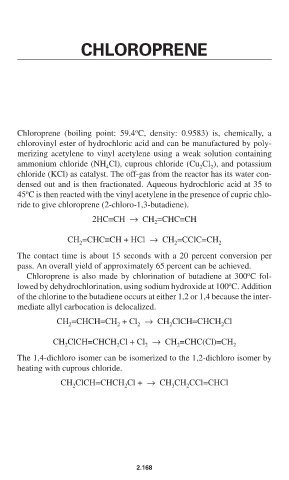

Chloroprene (boiling point: 59.4 C, density: 0.9583) is, chemically, a

chlorovinyl ester of hydrochloric acid and can be manufactured by poly-

merizing acetylene to vinyl acetylene using a weak solution containing

ammonium chloride (NH Cl), cuprous chloride (Cu Cl ), and potassium

4 2 2

chloride (KCl) as catalyst. The off-gas from the reactor has its water con-

densed out and is then fractionated. Aqueous hydrochloric acid at 35 to

o

45 C is then reacted with the vinyl acetylene in the presence of cupric chlo-

ride to give chloroprene (2-chloro-1,3-butadiene).

2HC≡CH → CH =CHC≡CH

2

CH =CHC≡CH + HCl → CH =CClC=CH

2 2 2

The contact time is about 15 seconds with a 20 percent conversion per

pass. An overall yield of approximately 65 percent can be achieved.

o

Chloroprene is also made by chlorination of butadiene at 300 C fol-

o

lowed by dehydrochlorination, using sodium hydroxide at 100 C. Addition

of the chlorine to the butadiene occurs at either 1,2 or 1,4 because the inter-

mediate allyl carbocation is delocalized.

CH =CHCH=CH + Cl → CH ClCH=CHCH Cl

2 2 2 2 2

CH ClCH=CHCH Cl + Cl → CH =CHC(Cl)=CH

2 2 2 2 2

The 1,4-dichloro isomer can be isomerized to the 1,2-dichloro isomer by

heating with cuprous chloride.

CH ClCH=CHCH Cl + → CH CH CCl=CHCl

2 2 3 2

2.168