Page 236 - Chemical and process design handbook

P. 236

Speight_Part II_C 11/7/01 3:08 PM Page 2.176

2.176 MANUFACTURE OF CHEMICALS

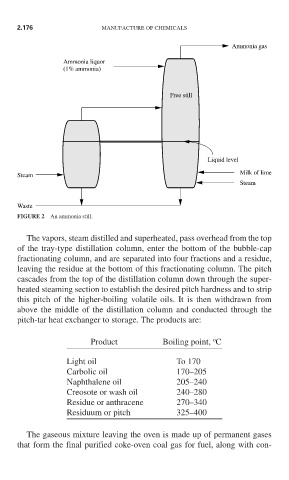

Ammonia gas

Ammonia liquor

(1% ammonia)

Free still

Liquid level

Milk of lime

Steam

Steam

Waste

FIGURE 2 An ammonia still.

The vapors, steam distilled and superheated, pass overhead from the top

of the tray-type distillation column, enter the bottom of the bubble-cap

fractionating column, and are separated into four fractions and a residue,

leaving the residue at the bottom of this fractionating column. The pitch

cascades from the top of the distillation column down through the super-

heated steaming section to establish the desired pitch hardness and to strip

this pitch of the higher-boiling volatile oils. It is then withdrawn from

above the middle of the distillation column and conducted through the

pitch-tar heat exchanger to storage. The products are:

o

Product Boiling point, C

Light oil To 170

Carbolic oil 170–205

Naphthalene oil 205–240

Creosote or wash oil 240–280

Residue or anthracene 270–340

Residuum or pitch 325–400

The gaseous mixture leaving the oven is made up of permanent gases

that form the final purified coke-oven coal gas for fuel, along with con-