Page 155 - Chemical engineering design

P. 155

FLOW-SHEETING

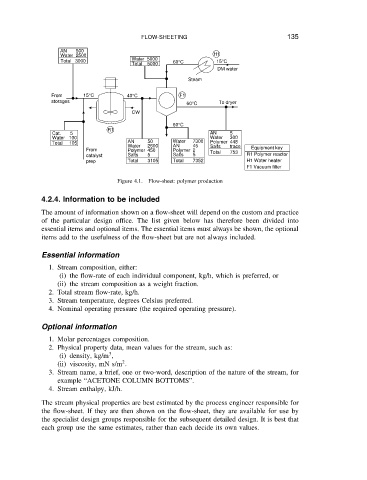

AN 500

Water 2500

Total 3000 Water 5000 60°C H1 135

15°C

Total 5000

DM water

Steam

From 15°C 40°C F1

storages To dryer

60°C

CW

60°C

R1

Cat. 5 AN 5

Water 100 Water 300

Total 105 AN 50 Water 7300 Polymer 448

Water 2600 AN 45 Salts trace Equipment key

From Polymer 450 Polymer 2 Total 753

catalyst Salts 5 Salts 5 R1 Polymer reactor

prep Total 3105 Total 7352 H1 Water heater

F1 Vacuum filter

Figure 4.1. Flow-sheet: polymer production

4.2.4. Information to be included

The amount of information shown on a flow-sheet will depend on the custom and practice

of the particular design office. The list given below has therefore been divided into

essential items and optional items. The essential items must always be shown, the optional

items add to the usefulness of the flow-sheet but are not always included.

Essential information

1. Stream composition, either:

(i) the flow-rate of each individual component, kg/h, which is preferred, or

(ii) the stream composition as a weight fraction.

2. Total stream flow-rate, kg/h.

3. Stream temperature, degrees Celsius preferred.

4. Nominal operating pressure (the required operating pressure).

Optional information

1. Molar percentages composition.

2. Physical property data, mean values for the stream, such as:

3

(i) density, kg/m ,

2

(ii) viscosity, mN s/m .

3. Stream name, a brief, one or two-word, description of the nature of the stream, for

example “ACETONE COLUMN BOTTOMS”.

4. Stream enthalpy, kJ/h.

The stream physical properties are best estimated by the process engineer responsible for

the flow-sheet. If they are then shown on the flow-sheet, they are available for use by

the specialist design groups responsible for the subsequent detailed design. It is best that

each group use the same estimates, rather than each decide its own values.