Page 266 - Chemical engineering design

P. 266

241

PIPING AND INSTRUMENTATION

5.2. Crude dichlorobenzene is pumped from a storage tank to a distillation column.

The tank is blanketed with nitrogen and the pressure above the liquid surface is

held constant at 0.1 bar gauge pressure. The minimum depth of liquid in the tank

is 1 m.

The distillation column operates at a pressure of 500 mmHg (500 mm of mercury,

absolute). The feed point to the column is 12 m above the base of the tank. The

tank and column are connected by a 50 mm internal diameter commercial steel

pipe, 200 m long. The pipe run from the tank to the column contains the following

Ž

valves and fittings: 20 standard radius 90 elbows; two gate valves to isolate the

pump (operated fully open); an orifice plate and a flow-control valve.

If the maximum flow-rate required is 20,000 kg/h, calculate the pump motor rating

(power) needed. Take the pump efficiency as 70 per cent and allow for a pressure

drop of 0.5 bar across the control valve and a loss of 10 velocity heads across the

orifice.

3

Density of the dichlorobenzene 1300 kg/m , viscosity 1.4 cp.

5.3. A liquid is contained in a reactor vessel at 115 bar absolute pressure. It is trans-

ferred to a storage vessel through a 50 mm internal diameter commercial steel pipe.

The storage vessel is nitrogen blanketed and pressure above the liquid surface is

2

kept constant at 1500 N/m gauge. The total run of pipe between the two vessels is

200 m. The miscellaneous losses due to entry and exit losses, fittings, valves, etc.,

amount to 800 equivalent pipe diameters. The liquid level in the storage vessel is

at an elevation 20 m below the level in the reactor.

A turbine is fitted in the pipeline to recover the excess energy that is available,

over that required to transfer the liquid from one vessel to the other. Estimate

the power that can be taken from the turbine, when the liquid transfer rate is

5000 kg/h. Take the efficiency of the turbine as 70%.

2

3

The properties of the fluid are: density 895 kg/m , viscosity 0.76 mNm s.

5.4. A process fluid is pumped from the bottom of one distillation column to another,

using a centrifugal pump. The line is standard commercial steel pipe 75 mm

internal diameter. From the column to the pump inlet the line is 25 m long and

contains six standard elbows and a fully open gate valve. From the pump outlet to

the second column the line is 250 m long and contains ten standard elbows, four

gate valves (operated fully open) and a flow-control valve. The fluid level in the

first column is 4 m above the pump inlet. The feed point of the second column is

6 m above the pump inlet. The operating pressure in the first column is 1.05 bara

and that of the second column 0.3 barg.

Determine the operating point on the pump characteristic curve when the flow is

2

such that the pressure drop across the control valve is 35 kN/m .

3

The physical properties of the fluid are: density 875 kg/m , viscosity

2

1.46 mN m s.

Also, determine the NPSH, at this flow-rate, if the vapour pressure of the fluid at

2

the pump suction is 25 kN/m .

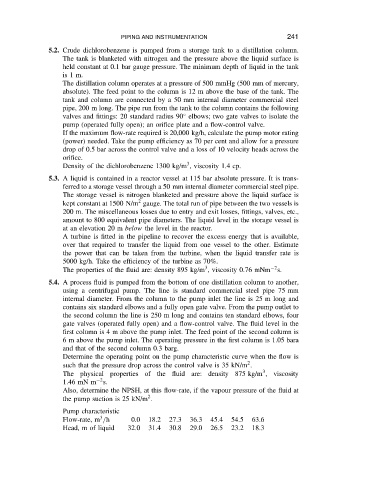

Pump characteristic

3

Flow-rate, m /h 0.0 18.2 27.3 36.3 45.4 54.5 63.6

Head, m of liquid 32.0 31.4 30.8 29.0 26.5 23.2 18.3