Page 41 - Chemical engineering design

P. 41

24

x

x

5

3

f

f 1 f 2 CHEMICAL ENGINEERING

f

4

3

x 6 Assumed

value

Calculated

x x x x

4

1

2

6

value

Figure 1.14.

x 3

x 4 x 1

x 5 f 4 f 2 f 1

x 4 x 2

x 6 x

6

f 3

x 3

x 5

Figure 1.15.

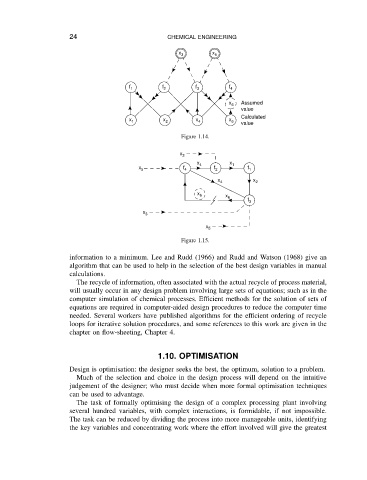

information to a minimum. Lee and Rudd (1966) and Rudd and Watson (1968) give an

algorithm that can be used to help in the selection of the best design variables in manual

calculations.

The recycle of information, often associated with the actual recycle of process material,

will usually occur in any design problem involving large sets of equations; such as in the

computer simulation of chemical processes. Efficient methods for the solution of sets of

equations are required in computer-aided design procedures to reduce the computer time

needed. Several workers have published algorithms for the efficient ordering of recycle

loops for iterative solution procedures, and some references to this work are given in the

chapter on flow-sheeting, Chapter 4.

1.10. OPTIMISATION

Design is optimisation: the designer seeks the best, the optimum, solution to a problem.

Much of the selection and choice in the design process will depend on the intuitive

judgement of the designer; who must decide when more formal optimisation techniques

can be used to advantage.

The task of formally optimising the design of a complex processing plant involving

several hundred variables, with complex interactions, is formidable, if not impossible.

The task can be reduced by dividing the process into more manageable units, identifying

the key variables and concentrating work where the effort involved will give the greatest