Page 67 - Chemical engineering design

P. 67

50

CHEMICAL ENGINEERING

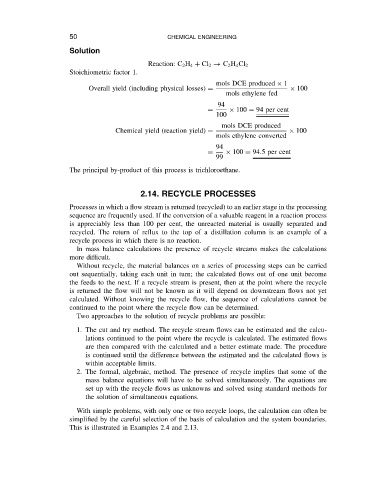

Solution

Reaction: C 2 H 4 C Cl 2 ! C 2 H 4 Cl 2

Stoichiometric factor 1.

mols DCE produced ð 1

Overall yield (including physical losses) D ð 100

mols ethylene fed

94

D ð 100 D 94 per cent

100

mols DCE produced

Chemical yield (reaction yield) D ð 100

mols ethylene converted

94

D ð 100 D 94.5 per cent

99

The principal by-product of this process is trichloroethane.

2.14. RECYCLE PROCESSES

Processes in which a flow stream is returned (recycled) to an earlier stage in the processing

sequence are frequently used. If the conversion of a valuable reagent in a reaction process

is appreciably less than 100 per cent, the unreacted material is usually separated and

recycled. The return of reflux to the top of a distillation column is an example of a

recycle process in which there is no reaction.

In mass balance calculations the presence of recycle streams makes the calculations

more difficult.

Without recycle, the material balances on a series of processing steps can be carried

out sequentially, taking each unit in turn; the calculated flows out of one unit become

the feeds to the next. If a recycle stream is present, then at the point where the recycle

is returned the flow will not be known as it will depend on downstream flows not yet

calculated. Without knowing the recycle flow, the sequence of calculations cannot be

continued to the point where the recycle flow can be determined.

Two approaches to the solution of recycle problems are possible:

1. The cut and try method. The recycle stream flows can be estimated and the calcu-

lations continued to the point where the recycle is calculated. The estimated flows

are then compared with the calculated and a better estimate made. The procedure

is continued until the difference between the estimated and the calculated flows is

within acceptable limits.

2. The formal, algebraic, method. The presence of recycle implies that some of the

mass balance equations will have to be solved simultaneously. The equations are

set up with the recycle flows as unknowns and solved using standard methods for

the solution of simultaneous equations.

With simple problems, with only one or two recycle loops, the calculation can often be

simplified by the careful selection of the basis of calculation and the system boundaries.

This is illustrated in Examples 2.4 and 2.13.