Page 74 - Chemical engineering design

P. 74

FUNDAMENTALS OF MATERIAL BALANCES

Step 9. Decide the basis of the calculation; see Section 2.7.

The order in which the steps are taken may be varied to suit the problem. 57

2.19. REFERENCES (FURTHER READING)

Basic texts

CHOPEY,N. P. (ed.) Handbook of Chemical Engineering Calculations (McGraw-Hill, 1984).

FELDER, R.M.and ROUSSEAU,R.W. Elementary Principles of Chemical Processes, 6th edn (Pearson, 1995).

HIMMELBLAU,D. M. Basic Principles and Calculations in Chemical Engineering (Prentice-Hall, 1982).

RUDD,D.F., POWERS,G.J.and SIIROLA,J.J. Process Synthesis (Prentice-Hall, 1973).

WHITWELL, J.C.and TONER,R.K. Conservation of Mass and Energy (McGraw-Hill, 1969).

WILLIAMS,E.T.and JACKSON,R.C. Stoichiometry for Chemical Engineers (McGraw-Hill, 1958).

Advanced texts

HENLEY, E.J.and ROSEN, E. M. (1969) Material and Energy Balance Computations (Wiley).

MYERS,A.L. and SEIDER, W. D. (1976) Introduction to Chemical Engineering and Computer Calculations

(Prentice-Hall).

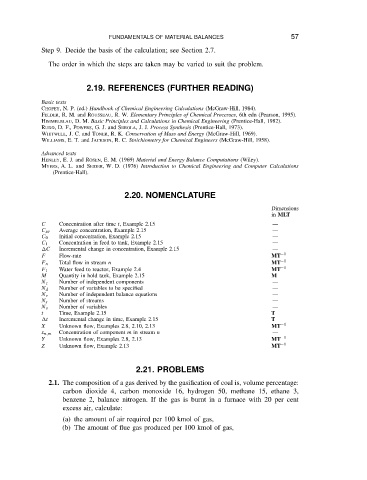

2.20. NOMENCLATURE

Dimensions

in MLT

C Concentration after time t, Example 2.15

C av Average concentration, Example 2.15

C 0 Initial concentration, Example 2.15

C 1 Concentration in feed to tank, Example 2.15

C Incremental change in concentration, Example 2.15

F Flow-rate MT 1

F n Total flow in stream n MT 1

1

F 1 Water feed to reactor, Example 2.4 MT

M Quantity in hold tank, Example 2.15 M

N c Number of independent components

N d Number of variables to be specified

N e Number of independent balance equations

N s Number of streams

Number of variables

N v

t Time, Example 2.15 T

t Incremental change in time, Example 2.15 T

X Unknown flow, Examples 2.8, 2.10, 2.13 MT 1

x n,m Concentration of component m in stream n

Y Unknown flow, Examples 2.8, 2.13 MT 1

Z Unknown flow, Example 2.13 MT 1

2.21. PROBLEMS

2.1. The composition of a gas derived by the gasification of coal is, volume percentage:

carbon dioxide 4, carbon monoxide 16, hydrogen 50, methane 15, ethane 3,

benzene 2, balance nitrogen. If the gas is burnt in a furnace with 20 per cent

excess air, calculate:

(a) the amount of air required per 100 kmol of gas,

(b) The amount of flue gas produced per 100 kmol of gas,