Page 81 - Chemical engineering design

P. 81

64

CHEMICAL ENGINEERING

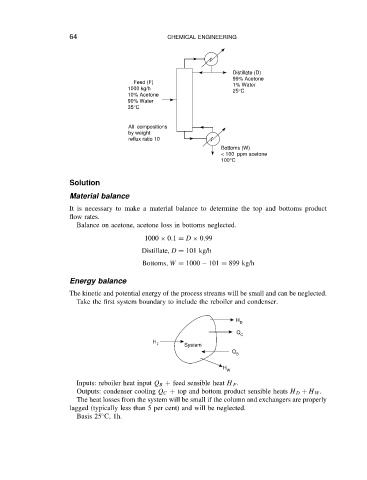

Distillate (D)

99% Acetone

Feed (F)

1% Water

1000 kg/h 25°C

10% Acetone

90% Water

35°C

All compositions

by weight

reflux ratio 10

Bottoms (W)

< 100 ppm acetone

100°C

Solution

Material balance

It is necessary to make a material balance to determine the top and bottoms product

flow rates.

Balance on acetone, acetone loss in bottoms neglected.

1000 ð 0.1 D D ð 0.99

Distillate,D D 101 kg/h

Bottoms,W D 1000 101 D 899 kg/h

Energy balance

The kinetic and potential energy of the process streams will be small and can be neglected.

Take the first system boundary to include the reboiler and condenser.

H D

Q

C

H

F System

Q

B

H

W

Inputs: reboiler heat input Q B C feed sensible heat H F .

Outputs: condenser cooling Q C C top and bottom product sensible heats H D C H W .

The heat losses from the system will be small if the column and exchangers are properly

lagged (typically less than 5 per cent) and will be neglected.

Ž

Basis 25 C, 1h.