Page 279 - Chiral Separation Techniques

P. 279

258 10 The Use of SMB for the Manufacture of Enantiopure Drug Substances: From …

The first modeling software which allowed for the optimization of nonlinear sep-

arations by SMB was presented in the early 1990s [46]. Today, numerous publica-

tions from academia allows one to have a better understanding of the SMB system

[47–51]. Industry now has the practical tools for modeling SMB for quick and effi-

cient process optimization [41, 52].

The Novasep team in 1994, successfully resolved 2 kg of racemic binaphthol per day

on a Pirkle-Type 3,5-DNBPG CSP (Merck KGaA, Germany) using a Licosep 8-200

SMB system (Summary report on the BRITE-EURAM project BRE2-CT92-0337).

10.3 SMB as a Development Tool

10.3.1 Basic Principles and Technical Aspects

In opposition to the “usual” (elution) chromatography, SMB is a continuous process,

and is thus much more adapted to large-scale production. Moreover, SMB is based

on a countercurrent contact between the liquid and the adsorbent, which leads to

lower eluent consumption.

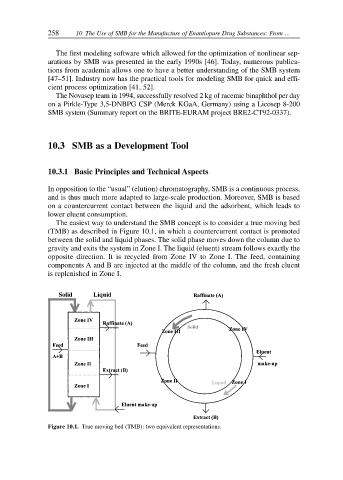

The easiest way to understand the SMB concept is to consider a true moving bed

(TMB) as described in Figure 10.1, in which a countercurrent contact is promoted

between the solid and liquid phases. The solid phase moves down the column due to

gravity and exits the system in Zone I. The liquid (eluent) stream follows exactly the

opposite direction. It is recycled from Zone IV to Zone I. The feed, containing

components A and B are injected at the middle of the column, and the fresh eluent

is replenished in Zone I.

Solid

Liquid

Figure 10.1. True moving bed (TMB): two equivalent representations.