Page 391 - Compression Machinery for Oil and Gas

P. 391

Drivers Chapter 7 369

Hot Gas Expanders

The idea of converting the energy in combustion exhaust gas to power has been

in practice for a century. Energy costs, environmental regulations, emissions

control, and carbon management have driven interests in employing hot gas

expanders in modern plants.

There are fundamental challenges to design a reliable expander operation:

the extreme high temperatures, chemical corrosion, and kinetic erosion caused

by the hot, particulate laden flue gas caused the rapid erosion of critical rotating

and stationary components such as the rotor disk, blades, and stator vanes. Dras-

tic thermal differentials also imposed substantial stress on the structural ele-

ments of the machine.

Corrosion is another critical consideration in expander operations. Corro-

sion is related to the high temperatures at which expanders operate. The effects

of creep and gaseous corrosion increase at elevated temperatures. The nature of

the corrosive attack is primarily influenced by the feedstock and the additives

injected during the cracking process. If not addressed, hot corrosion can lead to

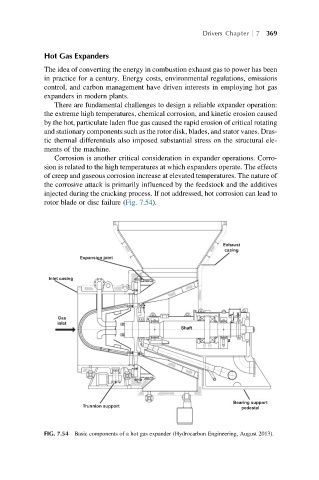

rotor blade or disc failure (Fig. 7.54).

Exhaust

casing

Expansion joint

Inlet casing

Gas

inlet

Shaft

Bearing support

Trunnion support

pedestal

FIG. 7.54 Basic components of a hot gas expander (Hydrocarbon Engineering, August 2013).