Page 127 - Construction Waterproofing Handbook

P. 127

3.16 CHAPTER THREE

materials such as granite to allow proper silicone penetration. Special mixes are manufac-

tured for use on limestone but also should be tested before actual application. Silicones can

yellow after application, aging, or weathering.

As with most sealers, substrates will turn white or discolor if applied during wet con-

ditions. Silicones do not have the capabilities to span or bridge cracking in a substrate.

Very porous materials, such as lightweight or split-face concrete blocks, are not acceptable

substrates for silicone sealer application. Adjacent surfaces such as windows and vegeta-

tion should be protected from overspray during application. (See Table 3.6.)

Urethanes

Urethane repellents, aliphatic or aromatic, are derivatives of carbonic acid, a colorless

crystalline compound. Clear urethane sealers are typically used for horizontal applications

but are also used on vertical surfaces. With a high solids content averaging 40 percent, they

1

have some ability to fill and span nonmoving cracks and fissures up to 16 in wide. High-solids

materials such as urethane sealers have low perm ratings and cause coating blistering if any

moisture or vapor drive occurs in the substrate.

Urethane sealers are film-forming materials that impart a high gloss to substrates,

and they are nonyellowing materials. They are applicable to most substrates including

wood and metal, but adhesive tests should be made before each application. Concrete

curing agents can create adhesion failures if the surface is not prepared by sandblasting

or acid etching.

Urethane sealers can also be applied over other compatible coatings, such as ure-

thane paints, for additional weather protection. They are resistant to many chemicals,

acids, and solvents and are used on stadium structures for both horizontal and vertical

seating sections. The cost of urethane materials has limited their use as sealers. (See

Table 3.7.)

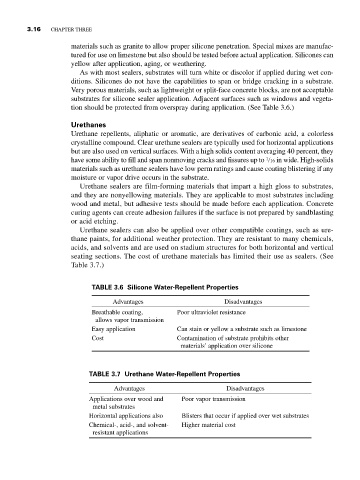

TABLE 3.6 Silicone Water-Repellent Properties

Advantages Disadvantages

Breathable coating, Poor ultraviolet resistance

allows vapor transmission

Easy application Can stain or yellow a substrate such as limestone

Cost Contamination of substrate prohibits other

materials’ application over silicone

TABLE 3.7 Urethane Water-Repellent Properties

Advantages Disadvantages

Applications over wood and Poor vapor transmission

metal substrates

Horizontal applications also Blisters that occur if applied over wet substrates

Chemical-, acid-, and solvent- Higher material cost

resistant applications