Page 136 - Construction Waterproofing Handbook

P. 136

ABOVE-GRADE WATERPROOFING 3.25

to exposed joints, then cured. Tape is then removed from the masonry units, leaving behind

a repaired joint surface with no change in wall facade color.

The thickness of coating added to mortar joints is variable but is greater when joints are

recessed. This system is applicable only to substrates in which the masonry units them-

selves, such as brick, are nondeteriorated and watertight, requiring no restoration.

Texture is easily added to a cementitious coating, either by coarseness of aggregate added

to the original mix or by application methods. The same cementitious mix applied by roller,

brush, spray, hopper gun, sponge, or trowel results in many different texture finishes. This

provides an owner or designer with many texture selections while maintaining adequate

waterproofing characteristics. A summary of the major advantages and disadvantages of

cementitious coatings are given in Table 3.12.

In certain instances, such as floor–wall

junctions, it is desirable first to apply the

cementitious coating to a substrate, and then to

fill the joint with sealant material in a color that

matches the cementitious coating. The coating

will fully adhere to the substrate and is com-

patible with sealant materials. It is also possible

first to apply cementitious coating to sub-

strates, then to apply a sealant to expansion

joints, door, and window penetrations, and

other joints. This is not possible with clear seal-

ers nor recommended with elastomeric coat-

ings, due to bonding problems.

Cementitious coatings are a better choice

over certain substrates, particularly concrete

or masonry, than clear sealers or elastomeric

coatings. This is because cementitious coat-

ings have better bonding strength, a longer

life cycle, lower maintenance, and less attrac-

tion of airborne contaminants. Provided that

adequate means are incorporated for thermal

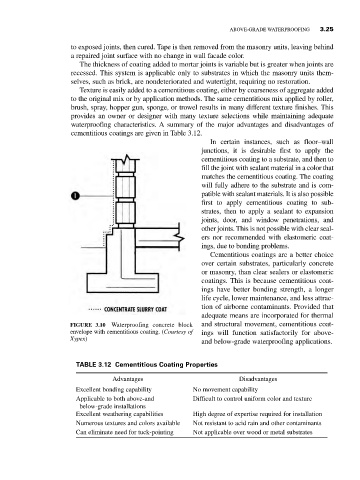

FIGURE 3.10 Waterproofing concrete block and structural movement, cementitious coat-

envelope with cementitious coating. (Courtesy of ings will function satisfactorily for above-

Xypex)

and below-grade waterproofing applications.

TABLE 3.12 Cementitious Coating Properties

Advantages Disadvantages

Excellent bonding capability No movement capability

Applicable to both above-and Difficult to control uniform color and texture

below-grade installations

Excellent weathering capabilities High degree of expertise required for installation

Numerous textures and colors available Not resistant to acid rain and other contaminants

Can eliminate need for tuck-pointing Not applicable over wood or metal substrates