Page 145 - Construction Waterproofing Handbook

P. 145

3.34 CHAPTER THREE

FIGURE 3.16 Changes in envelope plane require detailing prior to elastomeric applica-

tion. (Courtesy of Neogard)

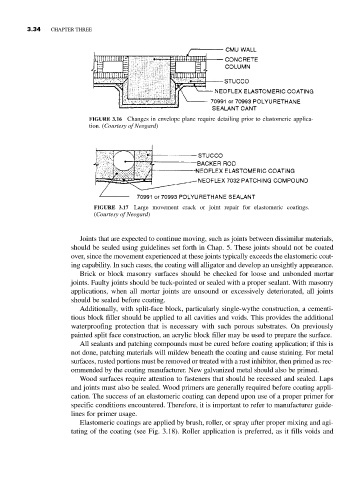

FIGURE 3.17 Large movement crack or joint repair for elastomeric coatings.

(Courtesy of Neogard)

Joints that are expected to continue moving, such as joints between dissimilar materials,

should be sealed using guidelines set forth in Chap. 5. These joints should not be coated

over, since the movement experienced at these joints typically exceeds the elastomeric coat-

ing capability. In such cases, the coating will alligator and develop an unsightly appearance.

Brick or block masonry surfaces should be checked for loose and unbonded mortar

joints. Faulty joints should be tuck-pointed or sealed with a proper sealant. With masonry

applications, when all mortar joints are unsound or excessively deteriorated, all joints

should be sealed before coating.

Additionally, with split-face block, particularly single-wythe construction, a cementi-

tious block filler should be applied to all cavities and voids. This provides the additional

waterproofing protection that is necessary with such porous substrates. On previously

painted split face construction, an acrylic block filler may be used to prepare the surface.

All sealants and patching compounds must be cured before coating application; if this is

not done, patching materials will mildew beneath the coating and cause staining. For metal

surfaces, rusted portions must be removed or treated with a rust inhibitor, then primed as rec-

ommended by the coating manufacturer. New galvanized metal should also be primed.

Wood surfaces require attention to fasteners that should be recessed and sealed. Laps

and joints must also be sealed. Wood primers are generally required before coating appli-

cation. The success of an elastomeric coating can depend upon use of a proper primer for

specific conditions encountered. Therefore, it is important to refer to manufacturer guide-

lines for primer usage.

Elastomeric coatings are applied by brush, roller, or spray after proper mixing and agi-

tating of the coating (see Fig. 3.18). Roller application is preferred, as it fills voids and