Page 220 - Construction Waterproofing Handbook

P. 220

ABOVE-GRADE WATERPROOFING 3.107

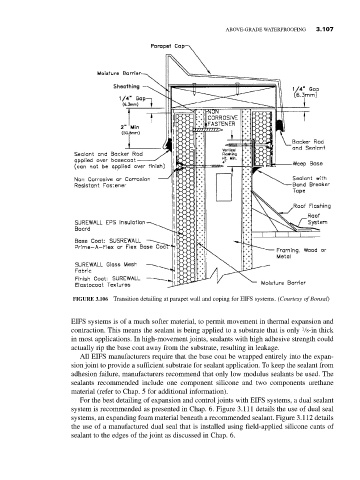

FIGURE 3.106 Transition detailing at parapet wall and coping for EIFS systems. (Courtesy of Bonsal)

EIFS systems is of a much softer material, to permit movement in thermal expansion and

1

contraction. This means the sealant is being applied to a substrate that is only 8-in thick

in most applications. In high-movement joints, sealants with high adhesive strength could

actually rip the base coat away from the substrate, resulting in leakage.

All EIFS manufacturers require that the base coat be wrapped entirely into the expan-

sion joint to provide a sufficient substrate for sealant application. To keep the sealant from

adhesion failure, manufacturers recommend that only low modulus sealants be used. The

sealants recommended include one component silicone and two components urethane

material (refer to Chap. 5 for additional information).

For the best detailing of expansion and control joints with EIFS systems, a dual sealant

system is recommended as presented in Chap. 6. Figure 3.111 details the use of dual seal

systems, an expanding foam material beneath a recommended sealant. Figure 3.112 details

the use of a manufactured dual seal that is installed using field-applied silicone cants of

sealant to the edges of the joint as discussed in Chap. 6.