Page 270 - Construction Waterproofing Handbook

P. 270

SEALANTS 5.29

Polysulfides withstand an average of 16–20 percent joint movement, with a joint design

of six times anticipated movement, versus a joint movement of 25 percent for urethanes

and joint design of four times anticipated movement.

As with other types of better sealants, polysulfides exceed the movement capabilities of

paints and therefore should not be painted. They are, however, manufactured in both one-

and two-component packaging in a wide range of colors. With two-component materials, a

color additive is blended in during mixing. Color charts are provided by the manufacturer.

Polysulfides are acceptable for a wide range of applications, including curtain wall

joints, precast panels, and poured-in-place concrete. Polysulfides require primers on all

substrates, and preparation is critical to allow successful adhesion and movement capabil-

ities of installed materials.

Manufacturers usually produce two types of primers—one for masonry, concrete,

and stone, and another for glazing, glass, and aluminum work. In a precast panel-to-

window-frame perimeter joint, two different types of primer on each side of the joint

would be required.

If properly prepared and installed, polysulfides will function in constantly immersed

joints. Of all commercially available sealants, polysulfides are best suited for total-

immersion joints. This includes swimming pools, water and wastewater treatment struc-

tures, fountains, and water containment ponds. Typically, two-component materials are

recommended for these types of joint installations.

Polysulfides should not be installed in joints that might have bituminous residue or con-

tamination, such as premold joint filler (e.g., concrete sidewalk joints). Polysulfides should

also not be applied over oil- or solvent-based joint sealants. Joint preparation for resealing

joints containing asphalt or oil-based products is especially critical if polysulfides are to

be used. Sandblasting or grinding of joints to remove all residues is necessary before appli-

cation of polysulfide materials.

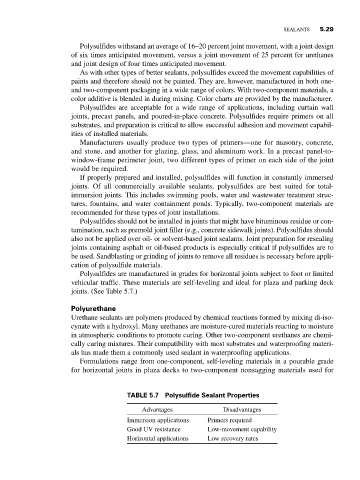

Polysulfides are manufactured in grades for horizontal joints subject to foot or limited

vehicular traffic. These materials are self-leveling and ideal for plaza and parking deck

joints. (See Table 5.7.)

Polyurethane

Urethane sealants are polymers produced by chemical reactions formed by mixing di-iso-

cynate with a hydroxyl. Many urethanes are moisture-cured materials reacting to moisture

in atmospheric conditions to promote curing. Other two-component urethanes are chemi-

cally curing mixtures. Their compatibility with most substrates and waterproofing materi-

als has made them a commonly used sealant in waterproofing applications.

Formulations range from one-component, self-leveling materials in a pourable grade

for horizontal joints in plaza decks to two-component nonsagging materials used for

TABLE 5.7 Polysulfide Sealant Properties

Advantages Disadvantages

Immersion applications Primers required

Good UV resistance Low-movement capability

Horizontal applications Low recovery rates