Page 301 - Construction Waterproofing Handbook

P. 301

EXPANSION JOINTS 6.5

manufacturers recommend joint widths of four times expected movement when the mate-

rial is capable of 25 percent movement in one direction.

Chapter 5 discusses the various sealant materials and their properties and uses. For hor-

izontal expansion joint applications, polyurethane sealants are commonly used. Urethanes

are capable of withstanding both pedestrian and vehicular traffic. They are compatible with

deck coatings, sealers, and protected membrane applications.

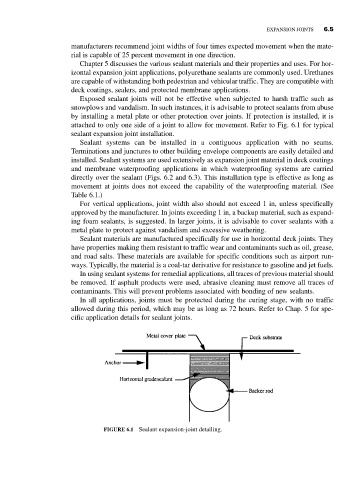

Exposed sealant joints will not be effective when subjected to harsh traffic such as

snowplows and vandalism. In such instances, it is advisable to protect sealants from abuse

by installing a metal plate or other protection over joints. If protection is installed, it is

attached to only one side of a joint to allow for movement. Refer to Fig. 6.1 for typical

sealant expansion joint installation.

Sealant systems can be installed in a contiguous application with no seams.

Terminations and junctures to other building envelope components are easily detailed and

installed. Sealant systems are used extensively as expansion joint material in deck coatings

and membrane waterproofing applications in which waterproofing systems are carried

directly over the sealant (Figs. 6.2 and 6.3). This installation type is effective as long as

movement at joints does not exceed the capability of the waterproofing material. (See

Table 6.1.)

For vertical applications, joint width also should not exceed 1 in, unless specifically

approved by the manufacturer. In joints exceeding 1 in, a backup material, such as expand-

ing foam sealants, is suggested. In larger joints, it is advisable to cover sealants with a

metal plate to protect against vandalism and excessive weathering.

Sealant materials are manufactured specifically for use in horizontal deck joints. They

have properties making them resistant to traffic wear and contaminants such as oil, grease,

and road salts. These materials are available for specific conditions such as airport run-

ways. Typically, the material is a coal-tar derivative for resistance to gasoline and jet fuels.

In using sealant systems for remedial applications, all traces of previous material should

be removed. If asphalt products were used, abrasive cleaning must remove all traces of

contaminants. This will prevent problems associated with bonding of new sealants.

In all applications, joints must be protected during the curing stage, with no traffic

allowed during this period, which may be as long as 72 hours. Refer to Chap. 5 for spe-

cific application details for sealant joints.

FIGURE 6.1 Sealant expansion-joint detailing.